Troubleshooting 10 Pin Ribbon Cable Male to Female in Complex Devices

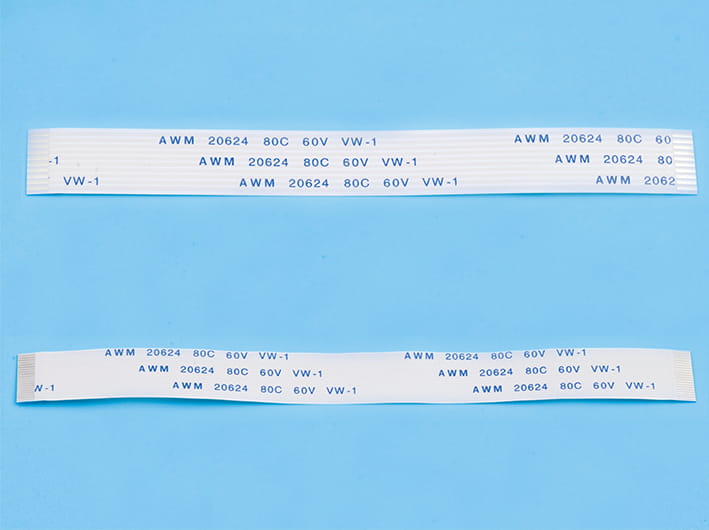

The 10 pin ribbon cable male to female stands as a critical link between various components within complex devices. Its counterpart, the 16 pin ribbon cable female to female, also plays a significant role in ensuring seamless data and power transfer. Troubleshooting these cables can be a daunting task, but with the right approach, it becomes a manageable process.

Understanding the Basics

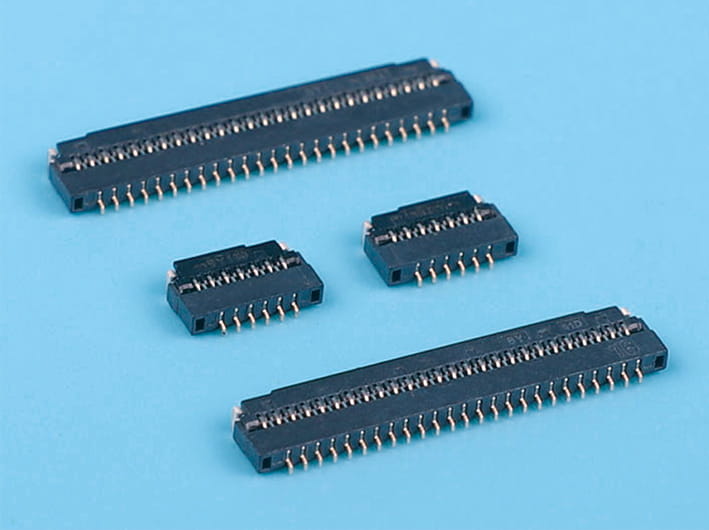

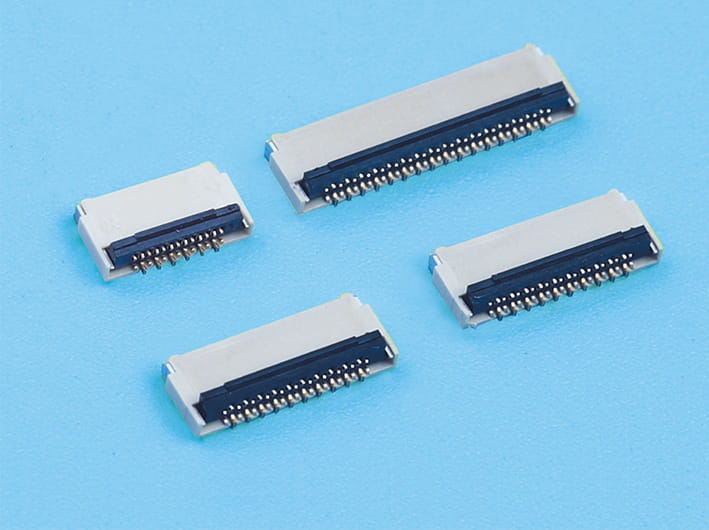

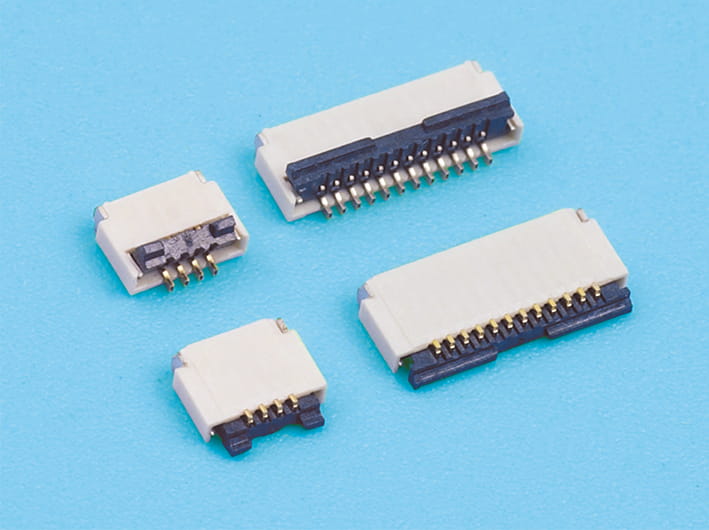

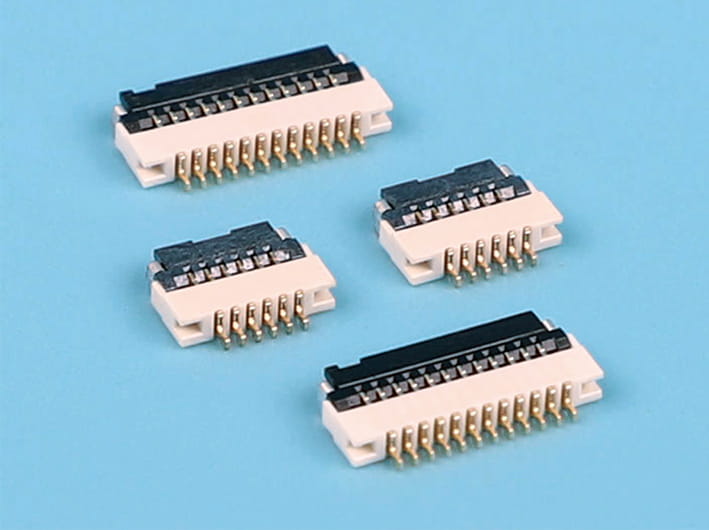

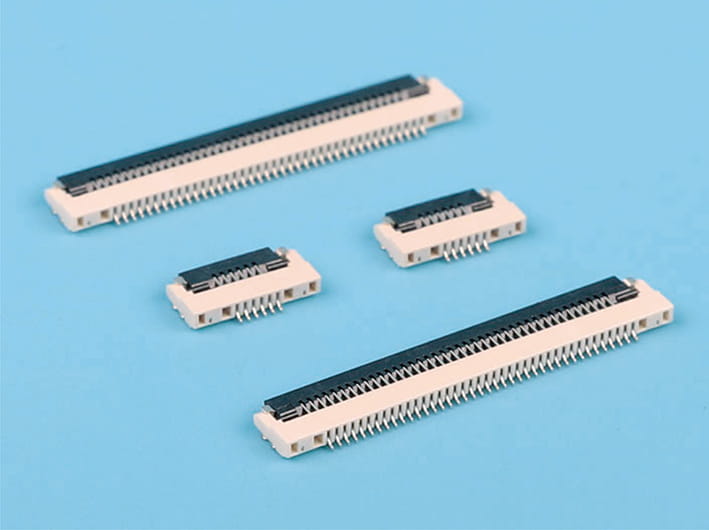

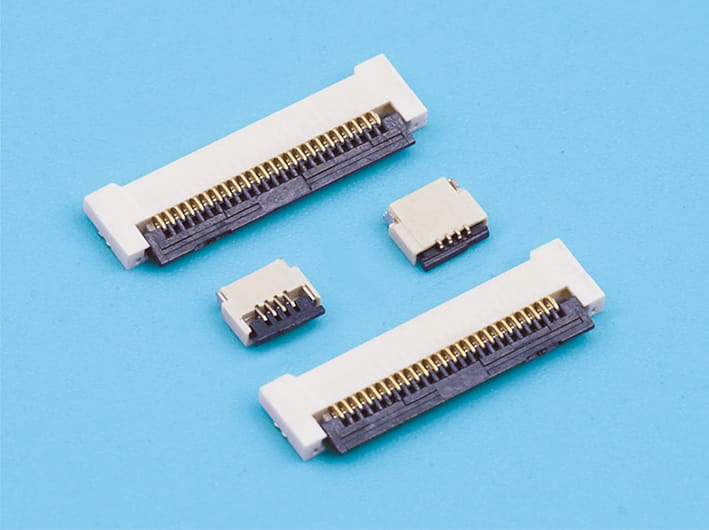

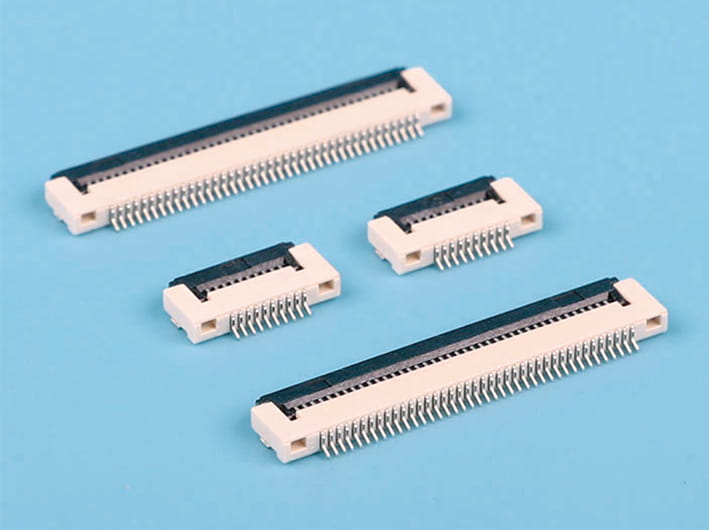

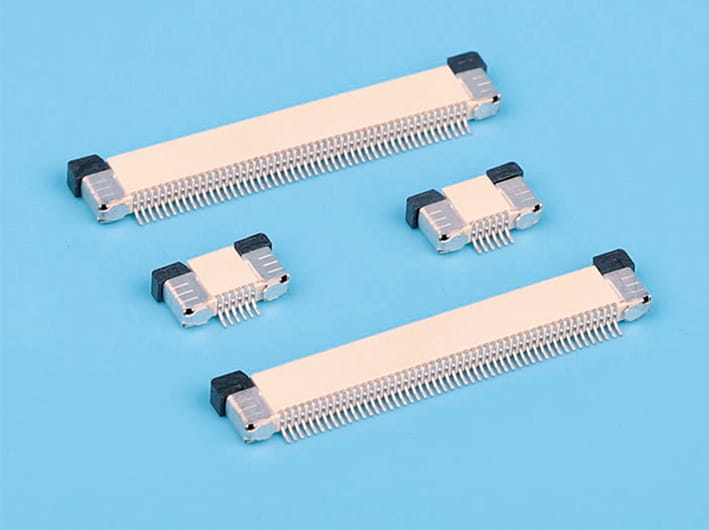

Before diving into troubleshooting, it's essential to understand the basics of 10 pin ribbon cable male to female connections. These cables are designed to provide a reliable and secure connection between male and female headers, facilitating data transfer in devices such as computers, printers, and other peripherals. Similarly, 16 pin ribbon cable female to female connections are used in applications where multiple female headers need to be linked, such as in high-density data storage or advanced computing systems.

Common Issues with 10 Pin Ribbon Cable Male to Female

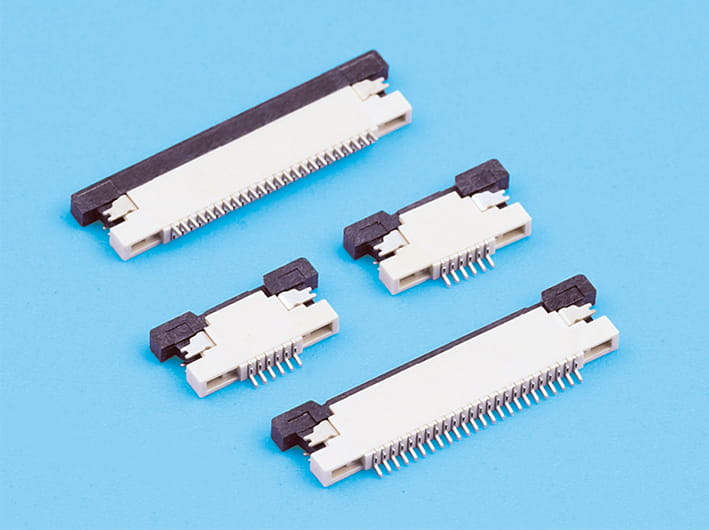

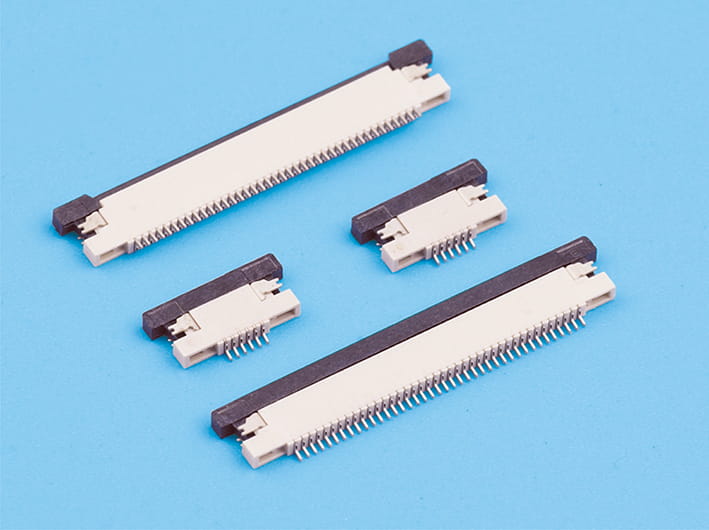

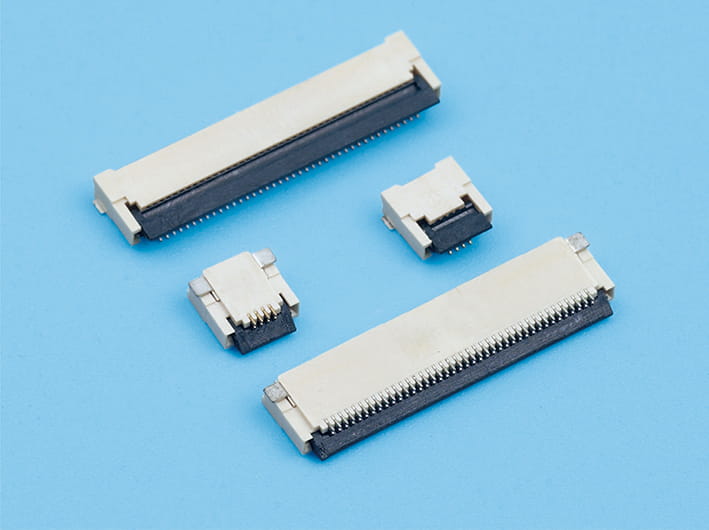

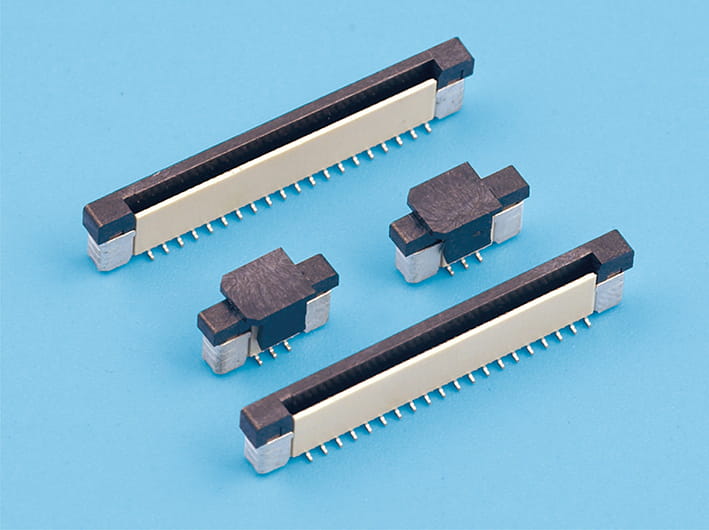

One of common issues with 10 pin ribbon cable male to female connections is poor contact due to bent or damaged pins. This can cause intermittent connections or complete failure to transfer data. To address this, it's crucial to inspect the male and female connectors for any visible damage. If pins are bent, they can often be gently straightened using precision tools. However, if the damage is severe, replacement of the 10 pin ribbon cable male to female is necessary.

Another frequent problem is dirt and debris buildup within the connectors. Over time, dust and other particles can accumulate, causing resistance and affecting the signal quality. Regular cleaning with compressed air or a soft brush can help maintain the integrity of the 10 pin ribbon cable male to female connections.

Troubleshooting 16 Pin Ribbon Cable Female to Female

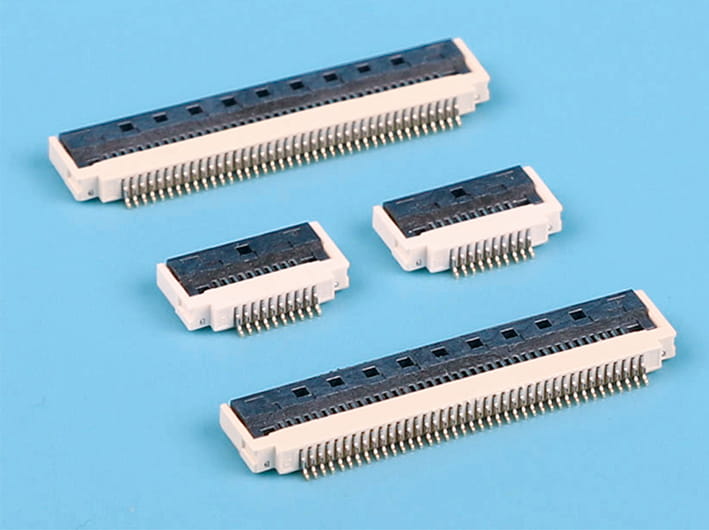

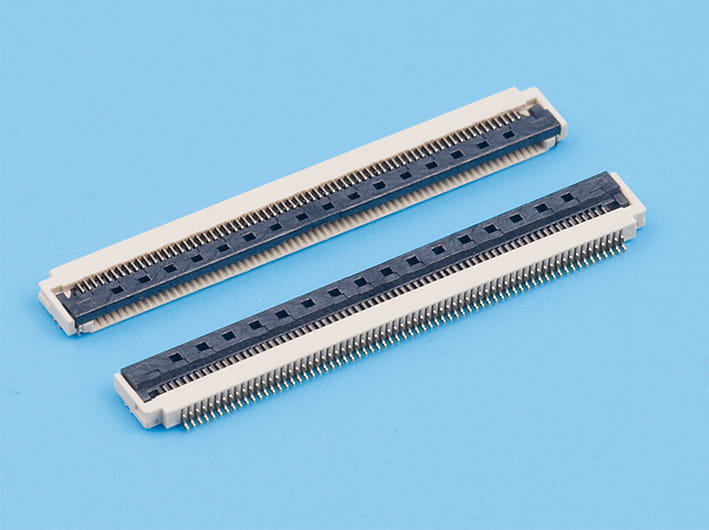

When it comes to 16 pin ribbon cable female to female connections, similar issues can arise. However, due to the higher pin count, these cables are more susceptible to crosstalk and signal interference. To mitigate this, ensure that the cables are of high quality and that the connectors are properly shielded. Additionally, maintaining the correct cable length can help reduce signal degradation over distance.

A less common but critical issue with 16 pin ribbon cable female to female connections is the misalignment of pins. This can occur if the connectors are forced into place without proper alignment, cause bent pins or broken connectors. Always ensure that the connectors are aligned correctly before inserting them.

Testing and Diagnostics

For both 10 pin ribbon cable male to female and 16 pin ribbon cable female to female connections, testing and diagnostics are essential steps in troubleshooting. Visual inspection should be followed by functional testing using appropriate diagnostic tools. This can include continuity testers, multimeters, and, in some cases, specialized software that can read the status of the connections.

Preventive Maintenance

To prevent issues with 10 pin ribbon cable male to female and 16 pin ribbon cable female to female connections, a regular maintenance schedule should be established. This includes periodic cleaning, inspection for physical damage, and checking for any signs of wear or fatigue. By catching issues early, costly repairs or replacements can be avoided.

In conclusion, troubleshooting 10 pin ribbon cable male to female connections in complex devices requires a methodical approach, combining visual inspection, testing, and preventive maintenance. By understanding the common issues and solutions associated with these cables, as well as their 16 pin ribbon cable female to female counterparts, technicians can ensure the reliability and longevity of the systems they support. As technology continues to evolve, the importance of maintaining and troubleshooting these critical connections will only grow, making it a vital skill for anyone working in the field of electronics.

English

English 中文简体

中文简体 Español

Español عربى

عربى