How to Maintain Battery Terminal Connecters for Long-Performance?

Battery terminal connectors are essential components in ensuring the smooth operation of electrical systems in devices like cars, motorcycles, and consumer electronics. Over time, these connectors may face wear due to corrosion, environmental exposure, or physical damage. Proper maintenance of battery terminal connectors is crucial for extending their lifespan and ensuring good performance.

Why Proper Maintenance Matters

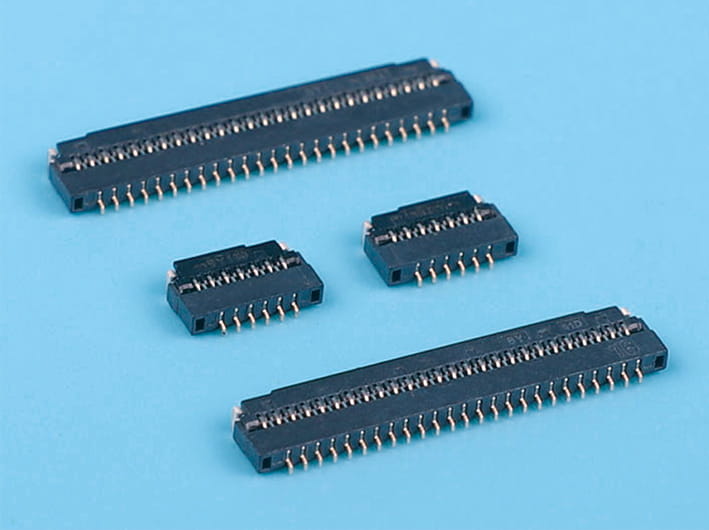

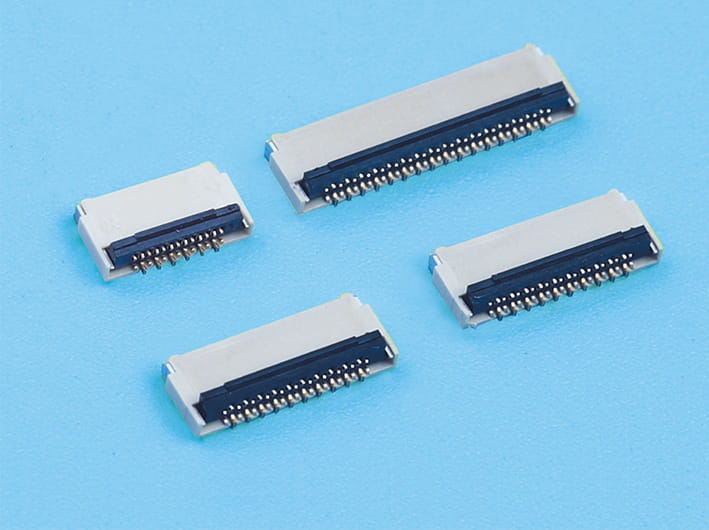

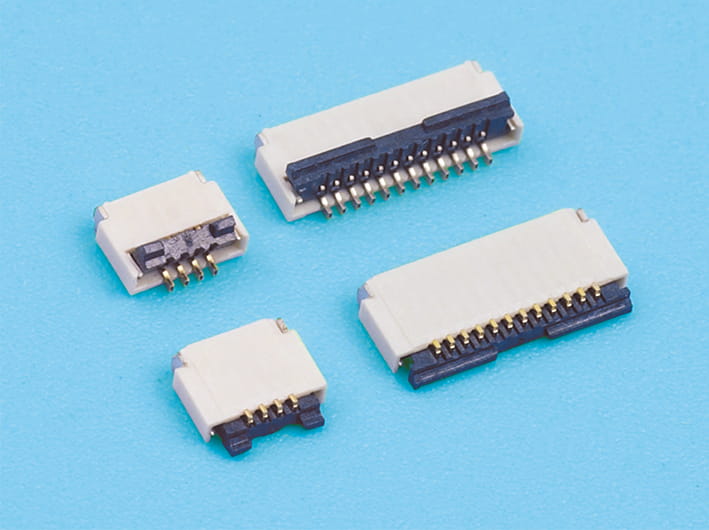

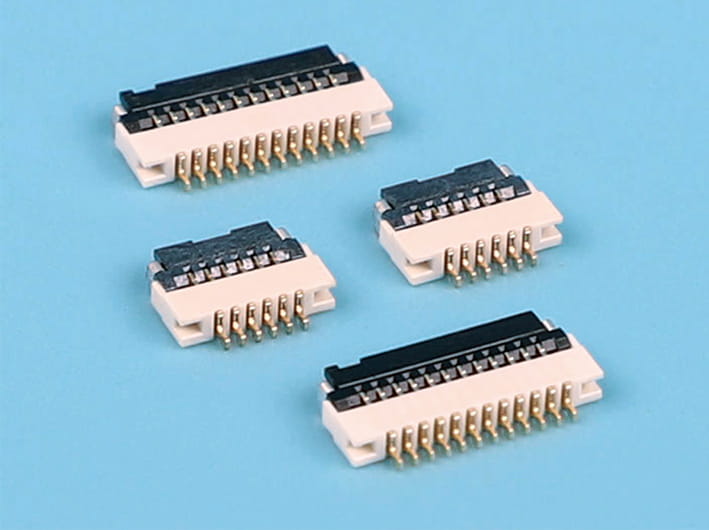

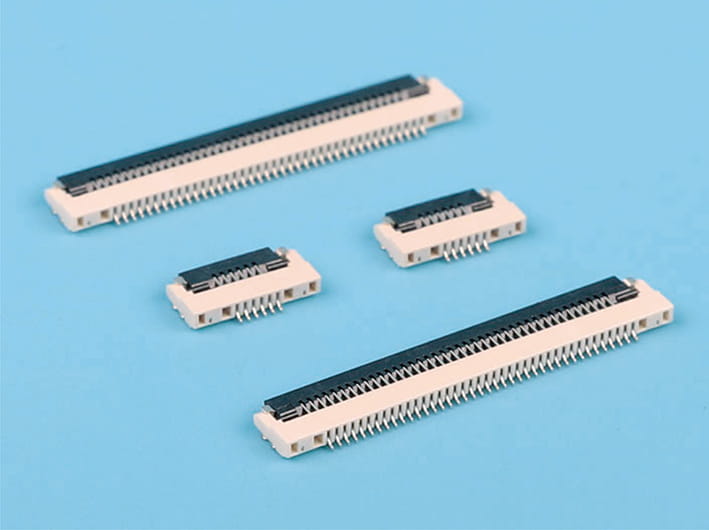

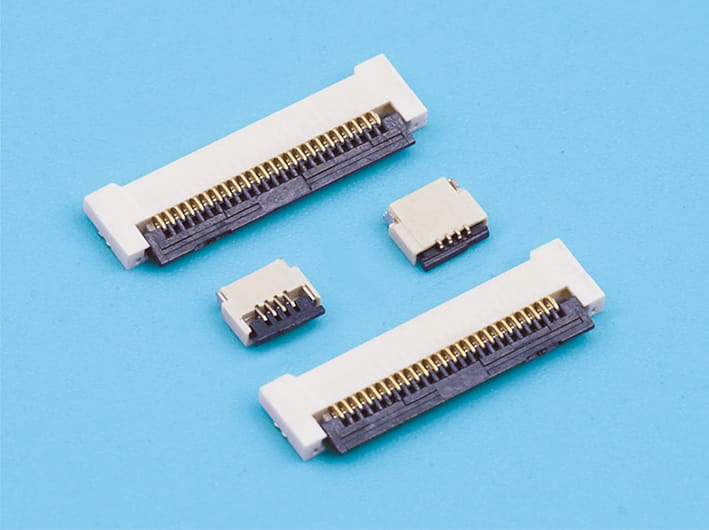

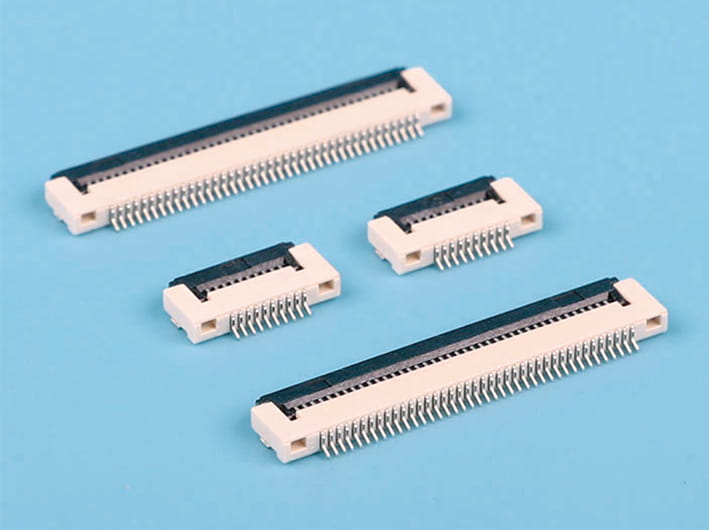

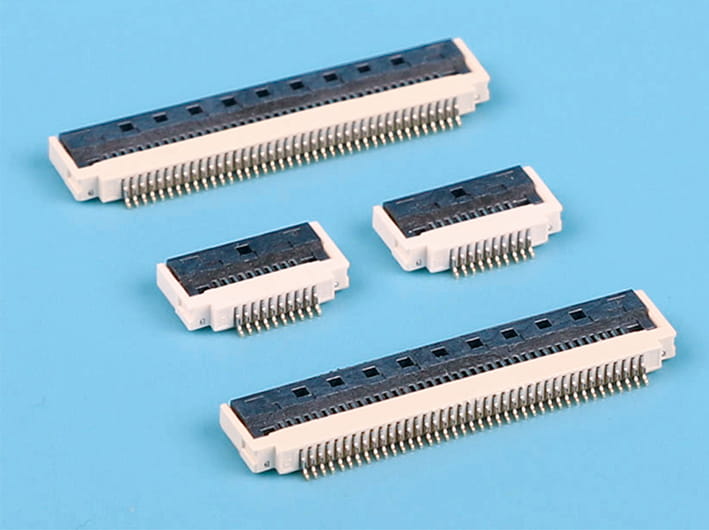

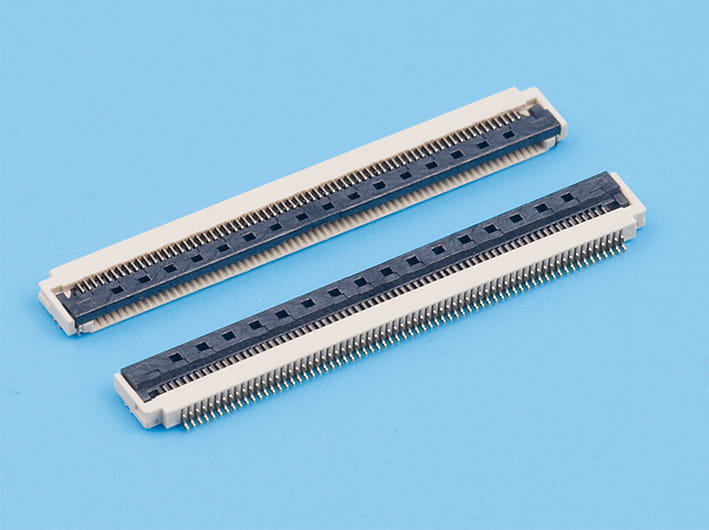

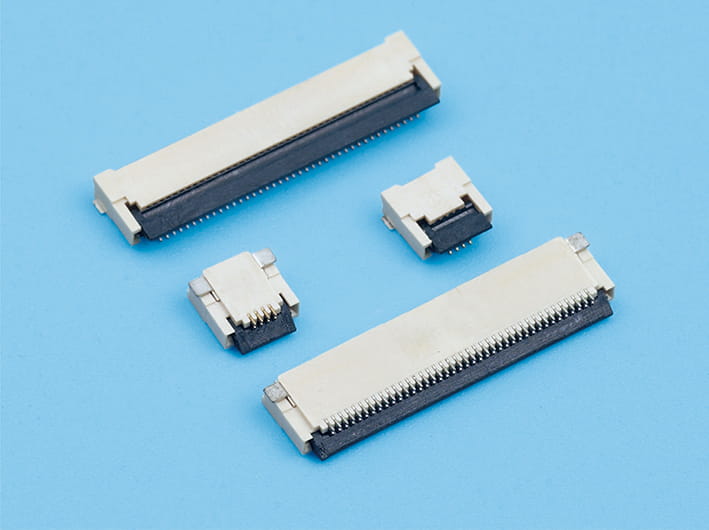

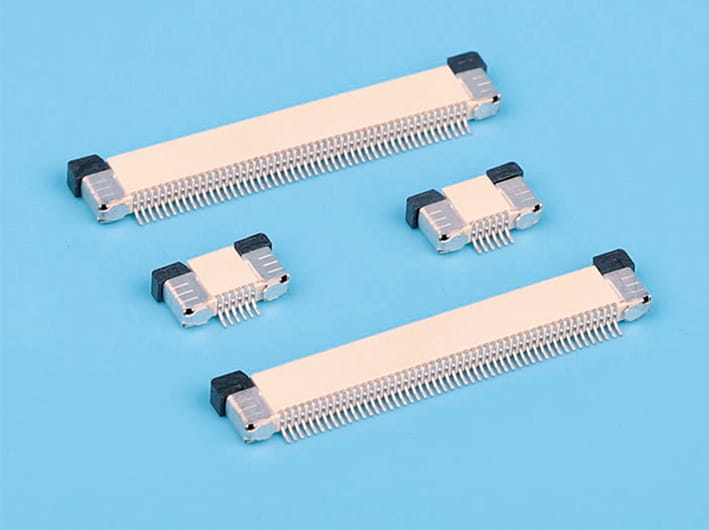

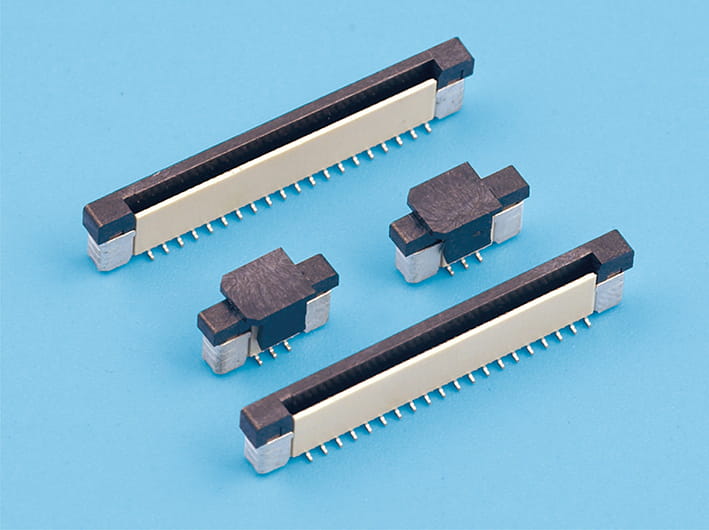

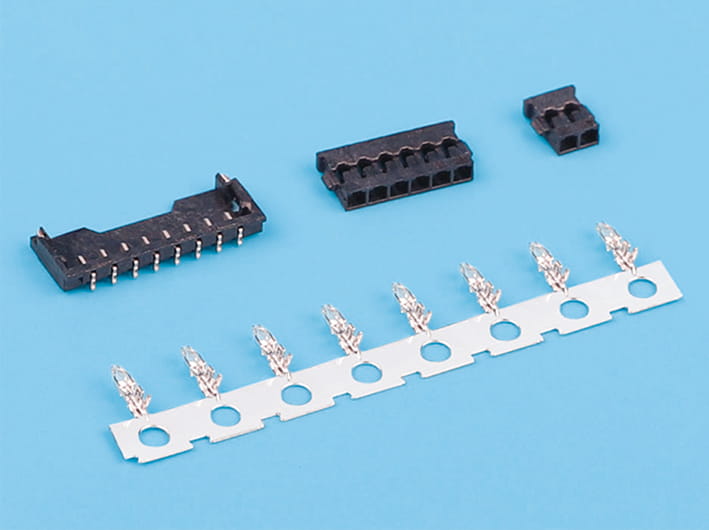

Battery terminal connectors are the link between a battery and the electrical system of a device. Poor maintenance can cause electrical issues, such as power loss, voltage fluctuations, or even failure. In micro battery connectors, typically found in portable electronics, neglecting proper care may cause poor connections. Flat battery connectors, often used in automotive or industrial applications, can suffer from corrosion and wear over time. Regular maintenance is crucial to ensure these connectors perform well.

Steps to Maintain Battery Terminal Connectors

1. Regular Inspection and Cleaning

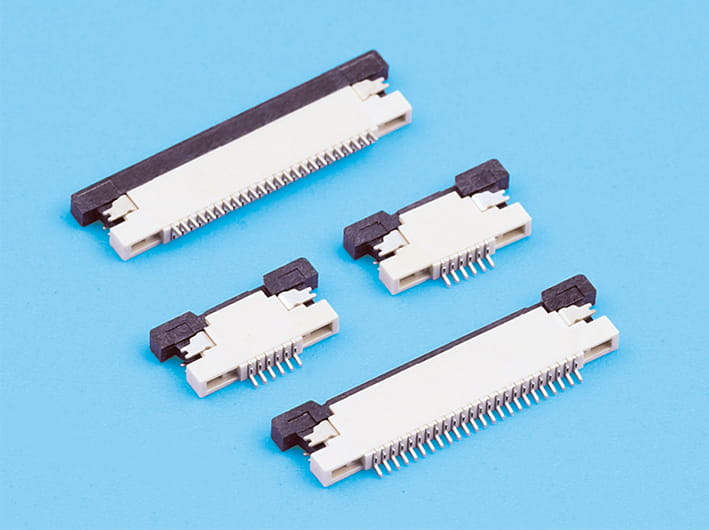

Inspect connectors regularly for signs of corrosion, rust, or dirt buildup. Flat battery connectors, exposed to various elements, are particularly prone to dirt. Use a soft cloth or brush to clean them, and if corrosion is present, use a baking soda and water mixture to dissolve it. After cleaning, rinse thoroughly and dry completely to prevent further corrosion.

For micro battery connectors, which are often used in small, delicate devices, cleaning should be done gently to avoid damaging the components. Keeping connectors clean helps maintain good electrical contact and performance.

2. Apply Anti-Corrosion Lubricant

Once connectors are cleaned, apply a thin layer of anti-corrosion lubricant. This prevents moisture and other corrosive agents from causing damage. Specialized battery terminal grease works well for battery terminal connectors, while micro battery connectors benefit from lubricants designed for small-scale applications. Flat battery connectors also benefit from this treatment, especially in environments.

Be sure to apply lubricant sparingly to avoid over-application, which could impair the connection quality.

3. Ensure Tight Connections

Loose connections are a common cause of performance issues. Battery terminal connectors should be securely fastened to the battery terminals to ensure reliable electrical contact. For flat battery connectors, ensure that the connector fits tightly to prevent intermittent contact. Tighten any loose connections to prevent power loss or other electrical issues.

Micro battery connectors should be handled carefully, as overtightening may damage the delicate components. A snug connection is enough for good performance.

4. Check for Wear and Tear

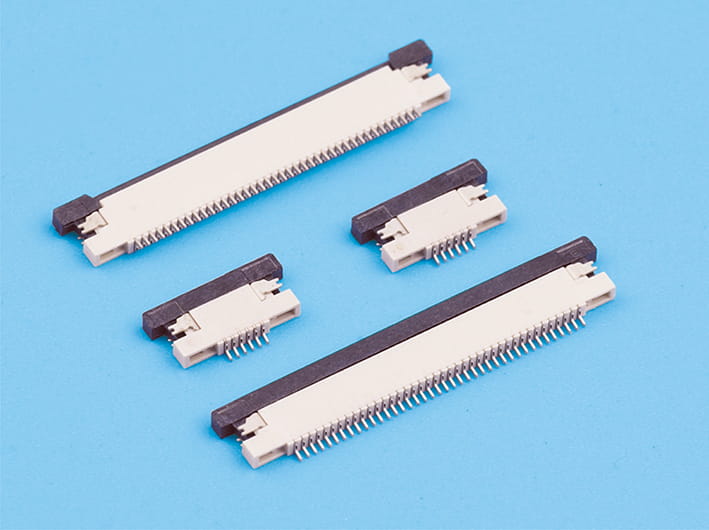

Inspect connectors regularly for physical damage such as cracks, fraying, or bent pins. If battery terminal connectors show signs of damage, replace them immediately to avoid electrical failures. Flat battery connectors and micro battery connectors should also be checked for degradation in their pins or sockets.

Worn-out connectors should be replaced promptly to prevent disruptions in device operation.

5. Protect Connectors from the Elements

Environmental factors like moisture, dust, and temperatures can damage battery terminal connectors. Protect connectors by using waterproof covers or enclosures. Flat battery connectors, often exposed to harsh conditions in automotive or industrial settings, can benefit from additional shielding.

Micro battery connectors should be protected from moisture and physical stress, especially when used in portable devices. Using protective casings can prolong the connectors' life.

Maintaining battery terminal connectors is essential for reliable device operation. Regular cleaning, lubrication, and inspection for damage will help ensure long-performance. Micro battery connectors and flat battery connectors also benefit from these practices, extending the life of the device they power. By following these simple maintenance steps, users can prevent costly repairs and ensure that their devices function smoothly for years to come. Proper care and attention to connectors help avoid unexpected breakdowns and improve the overall lifespan of electrical systems.

English

English 中文简体

中文简体 Español

Español عربى

عربى