Spade Crimp Terminals: Tips for Proper Installation and Maintenance

In the intricate world of electrical connections, spade crimp terminals and double crimp terminals stand out as essential components for secure and reliable wiring. These terminals are not just connectors; they are the lifelines of any electrical system, ensuring that power flows smoothly and safely.

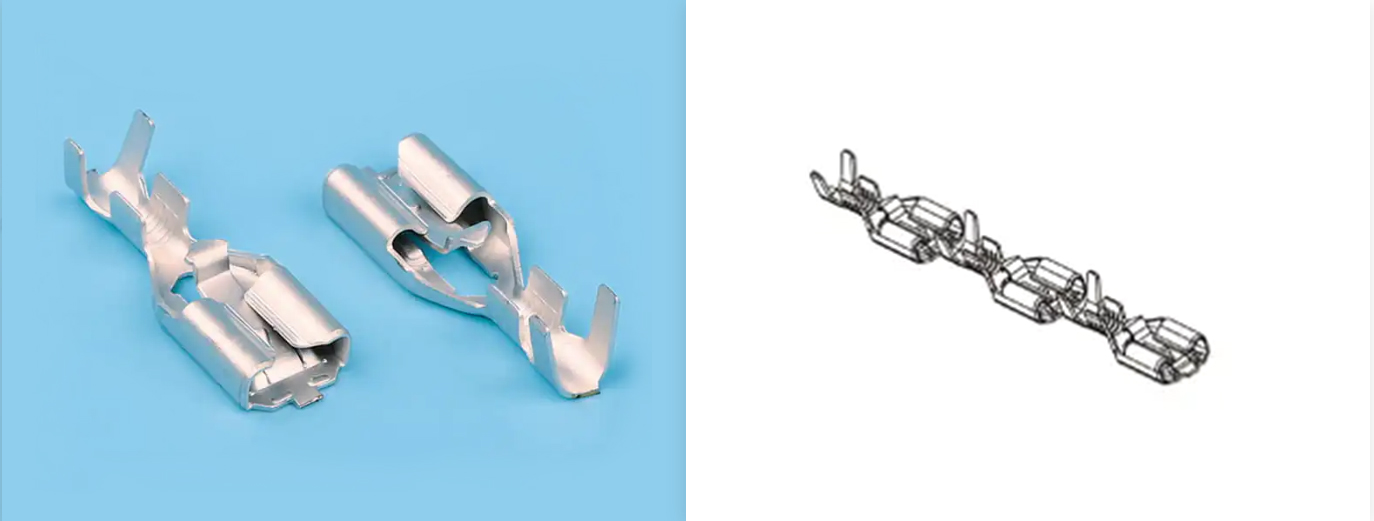

Understanding Spade Crimp Terminals

Spade crimp terminals are widely recognized for their distinctive shape, which resembles a spade. These terminals are designed to provide a strong and secure connection, especially in applications where high current loads are common. The spade crimp terminal's broad contact area reduces resistance and heat build-up, making it ideal for heavy-duty use. On the other hand, double crimp terminals offer an additional layer of security with their dual crimp design, which ensures a more robust connection.

Installation Best Practices

When it comes to installing spade crimp terminals, precision and care are paramount. Here are some tips to ensure a proper installation:

1. Preparation: Before you begin, ensure that the wire is stripped correctly, leaving the right amount of exposed copper. This is crucial for a good connection.

2. Crimping: Use the appropriate crimp tool for the size of your spade crimp terminal. Improper tools can cause weak or unreliable connections. For double crimp terminals, ensure that both sides are crimped securely.

3. Inspection: After crimping, inspect the spade crimp terminal to ensure that it is fully and evenly crimped. A poor crimp can cause a high-resistance connection, which can cause heat and potential failure.

4. Torque: When tightening the terminal to the connector, use the correct torque as specified by the manufacturer. Over-tightening can damage the terminal, while under-tightening can result in a loose connection.

5. Compatibility: Always use spade crimp terminals that are compatible with the wire gauge and the connector type. Mixing and matching can cause subgood performance and potential safety hazards.

Maintenance and Troubleshooting

Proper maintenance is key to the longevity and reliability of spade crimp terminals and double crimp terminals. Here are some maintenance tips:

1. Regular Checks: Periodically inspect the terminals for signs of wear, corrosion, or damage. Early detection can prevent more significant issues down the line.

2. Cleaning: Keep the terminals clean and free from dirt and debris. This can help prevent corrosion and ensure a good connection.

3. Lubrication: Apply a small amount of lubricant to the terminals if they are in a high-wear environment. This can help reduce friction and prolong the life of the connection.

4. Replacement: If a spade crimp terminal or double crimp terminal shows signs of significant wear or damage, replace it immediately. A compromised terminal can cause poor connections and potential electrical failures.

5. Training: Ensure that all personnel involved in the installation and maintenance of spade crimp terminals and double crimp terminals are properly trained. Knowledge is power when it comes to electrical safety and efficiency.

Spade crimp terminals and double crimp terminals are critical components in any electrical system, and their proper installation and maintenance are essential for ensuring the safety and reliability of the connections they make. By following the tips provided in this article, professionals can ensure that their electrical systems are as efficient and secure as possible. Remember, a well-maintained electrical system starts with the right spade crimp terminal or double crimp terminal, installed and cared for correctly.

English

English 中文简体

中文简体 Español

Español عربى

عربى