How Brass Crimp Connectors Ensure Durability in Electrical Assemblies

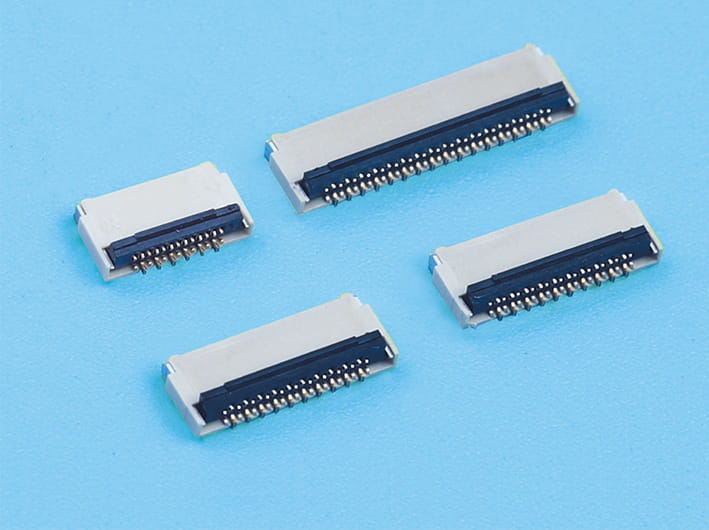

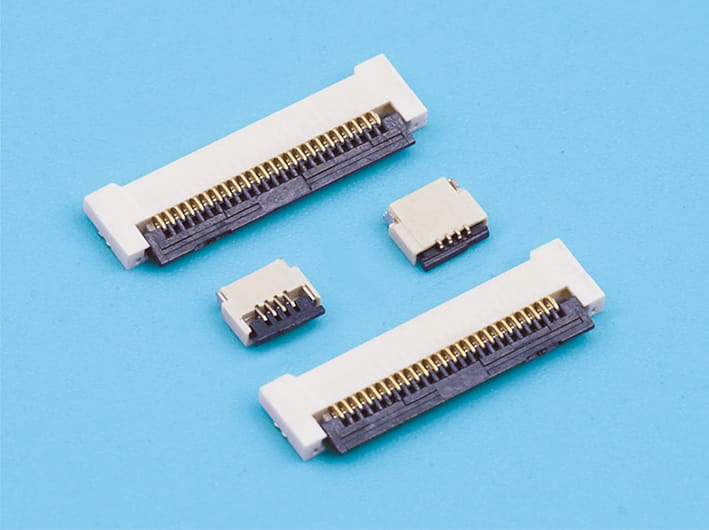

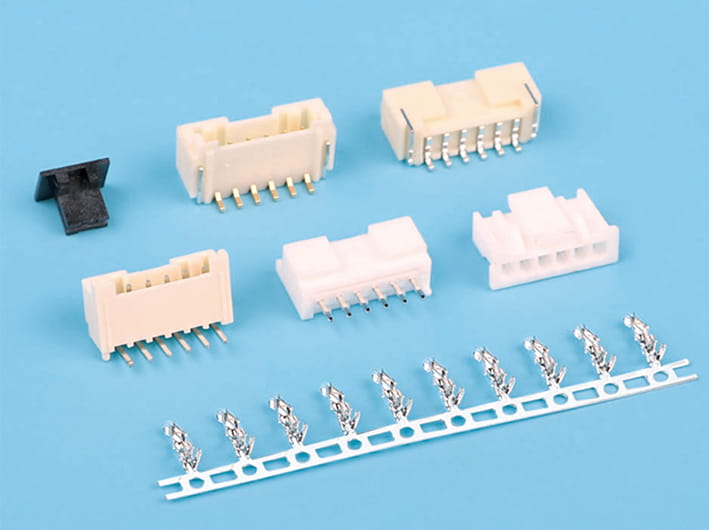

Brass crimp connectors are chosen for their exceptional properties, which include high conductivity, corrosion resistance, and mechanical strength. These attributes make brass an ideal material for creating connectors that can withstand the test of time. In electrical assemblies, brass crimp connectors are often the preferred choice for their ability to maintain a secure connection under various environmental conditions.

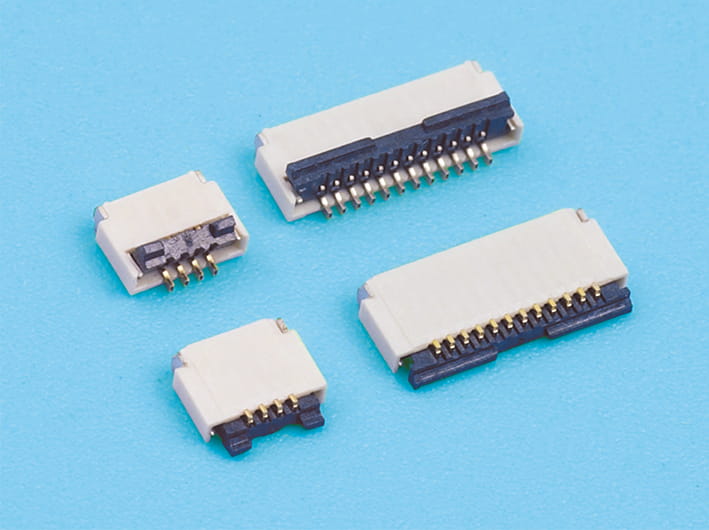

Battery crimp connectors play a critical role in the energy transfer from batteries to the devices they power. These connectors must be able to handle high currents and voltages without failure. Brass, with its outstanding electrical conductivity, ensures that power is transferred efficiently with minimal loss. The durability of brass crimp connectors is further enhanced by their resistance to corrosion, which is particularly important in environments where moisture or chemicals may be present.

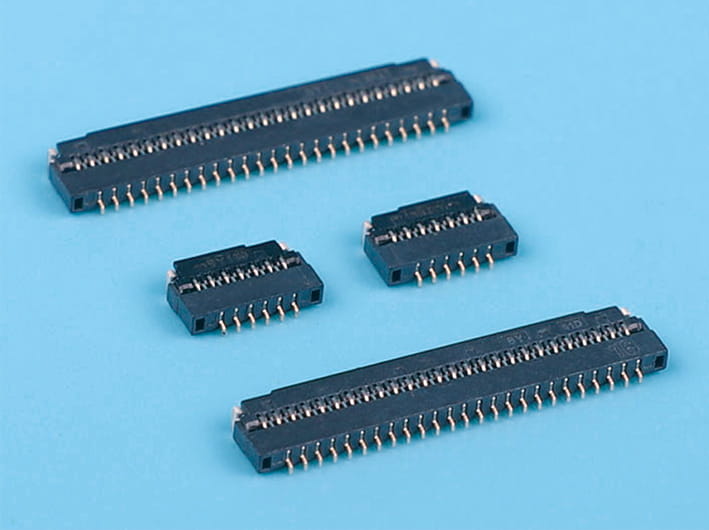

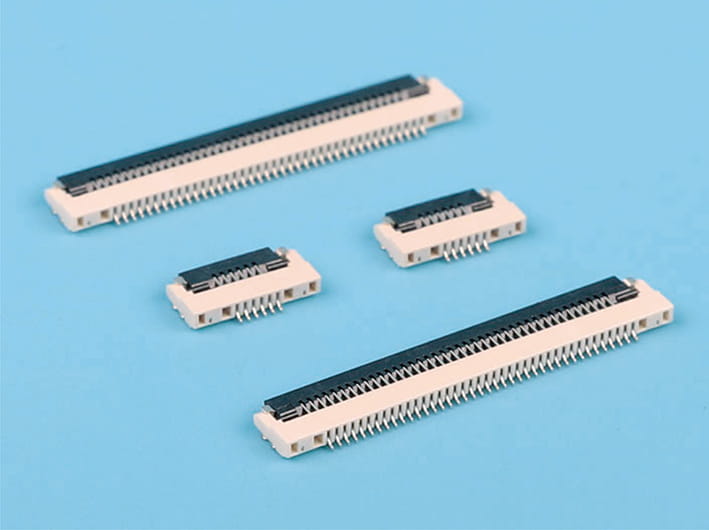

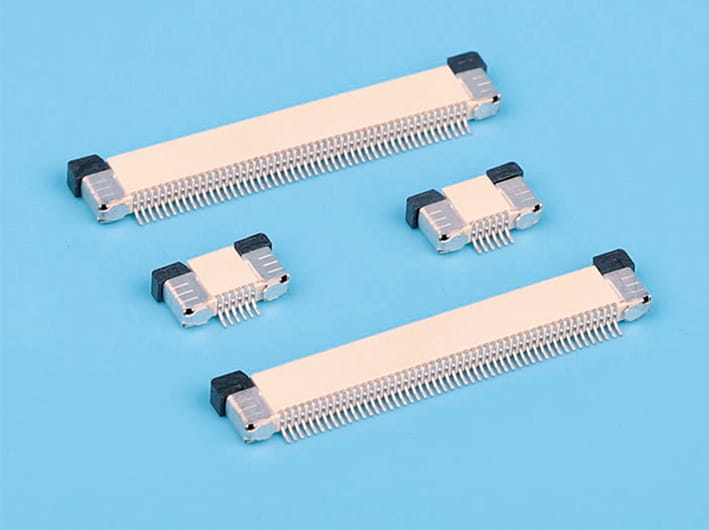

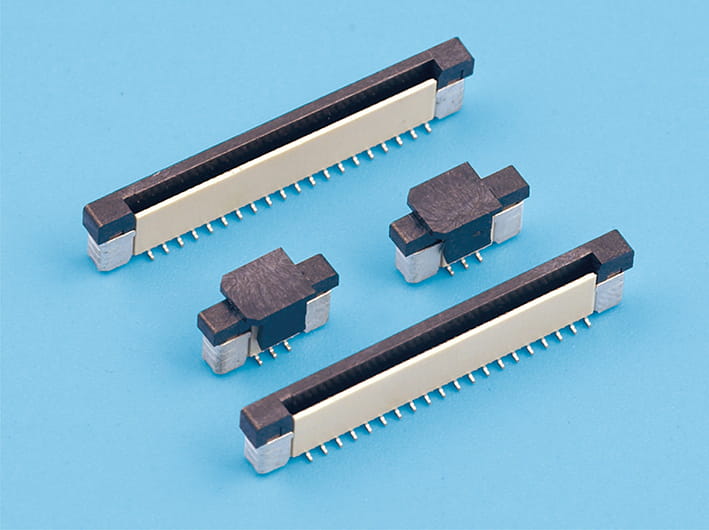

Cable crimp terminals are the interface between wires and the devices they connect. They must be able to handle the stress of repeated connections and disconnections without losing their integrity. Brass crimp connectors, with their robust mechanical strength, are up to this task. The crimping process ensures a secure connection, and the brass material resists wear and tear, making these terminals a reliable choice for long-use.

The durability of brass crimp connectors, battery crimp connectors, and cable crimp terminals is not just about the material; it also depends on the quality of the crimping process. Proper crimping is essential to ensure a secure and lasting connection. Technicians must use the correct tools and follow established procedures to crimp these connectors effectively. A poorly crimped connection can cause a weak link in the electrical assembly, which can result in failure over time.

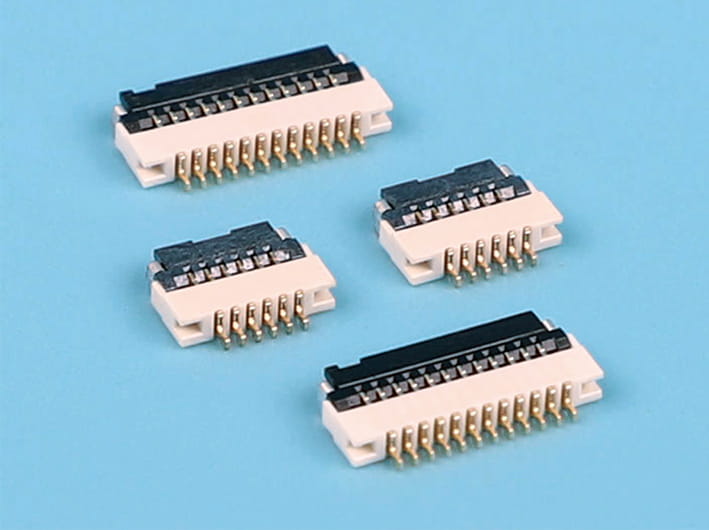

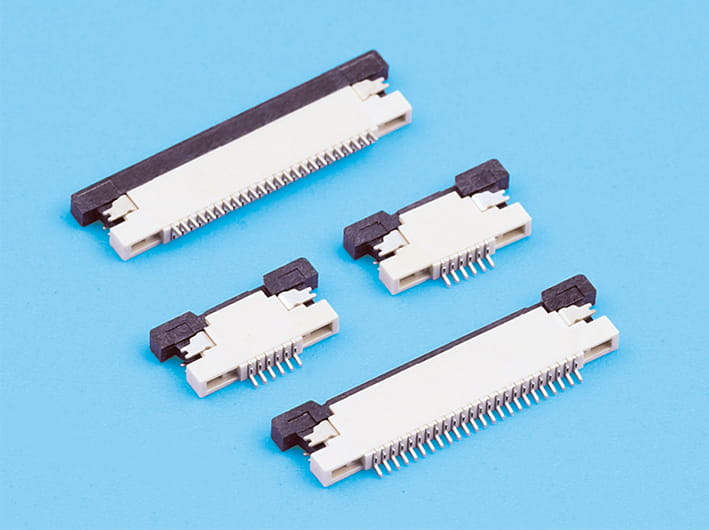

Regular maintenance and inspection are crucial to maintaining the durability of brass crimp connectors. Over time, connectors can become loose or corroded, which can compromise their performance. By regularly checking for signs of wear and ensuring that connections remain secure, technicians can extend the life of these connectors and the electrical assemblies they are a part of.

The environment in which brass crimp connectors, battery crimp connectors, and cable crimp terminals are used can have a significant impact on their durability. Exposure to temperatures, humidity, and corrosive substances can accelerate the degradation of connectors. However, brass is known for its resistance to these factors, making it a preferred material for connectors used in harsh environments.

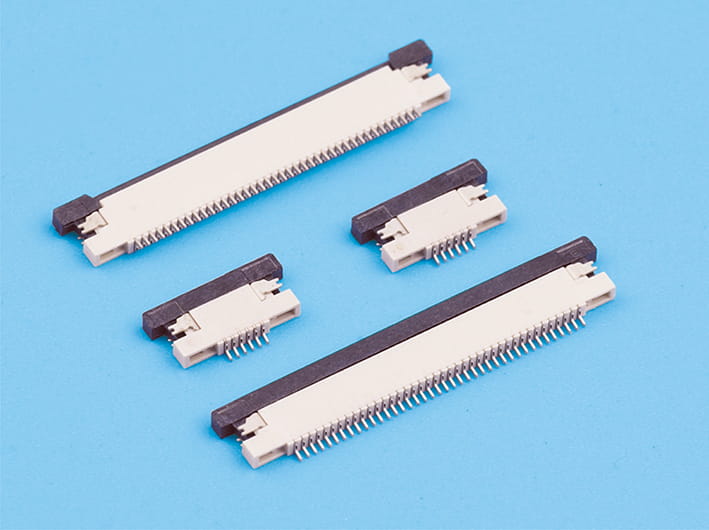

As technology advances, the demand for more reliable and durable electrical connections grows. Brass crimp connectors, with their proven track record, are poised to continue playing a vital role in the future of electrical assemblies. Innovations in material science and crimping technology will likely further enhance the performance and longevity of these connectors.

The brass crimp connectors, battery crimp connectors, and cable crimp terminals are the cornerstone of durable electrical assemblies. Their resilience is a result of the material's inherent properties and the precision of the crimping process. By understanding the importance of proper installation and maintenance, technicians can ensure that these connectors continue to provide reliable service for years to come. As the electrical industry evolves, the role of brass crimp connectors will remain pivotal, powering the devices and systems that drive modern life.

English

English 中文简体

中文简体 Español

Español عربى

عربى