How to Install and Maintain FPC FFC Connectors Effectively?

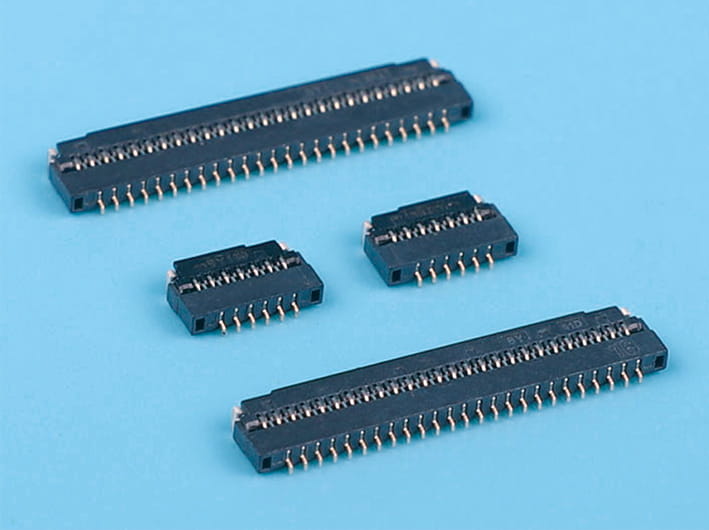

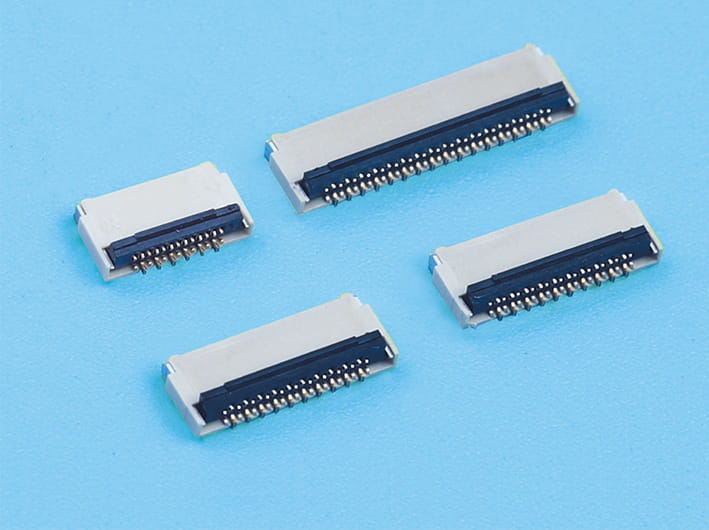

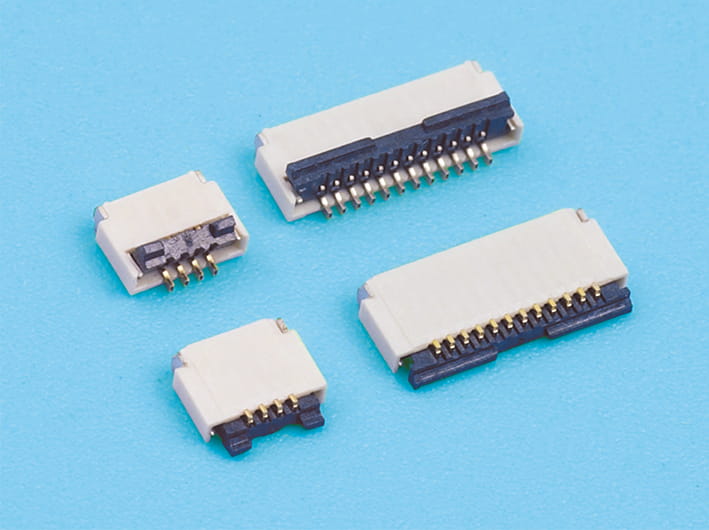

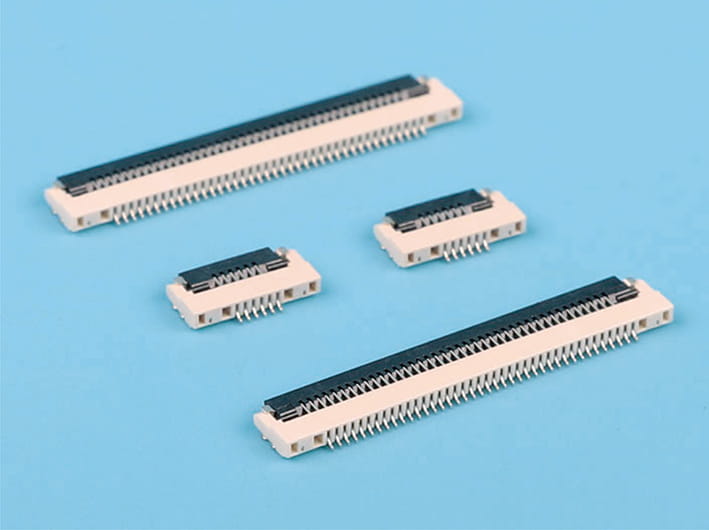

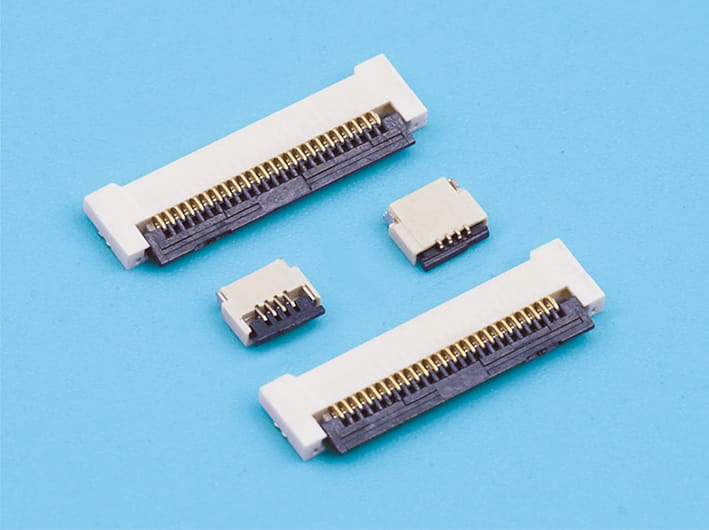

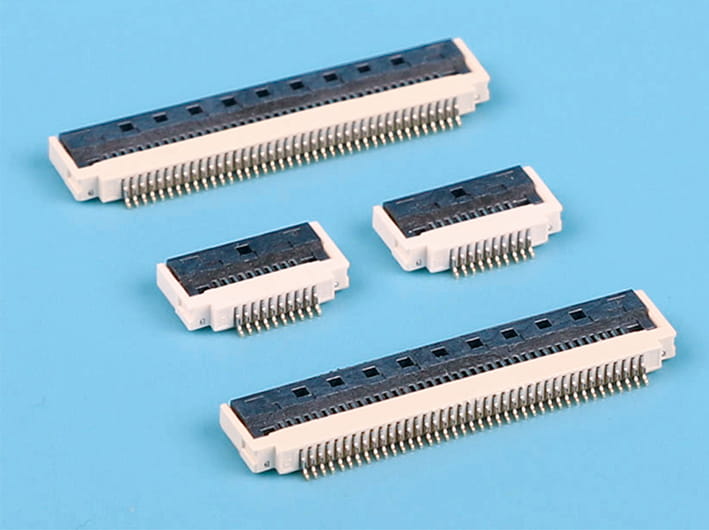

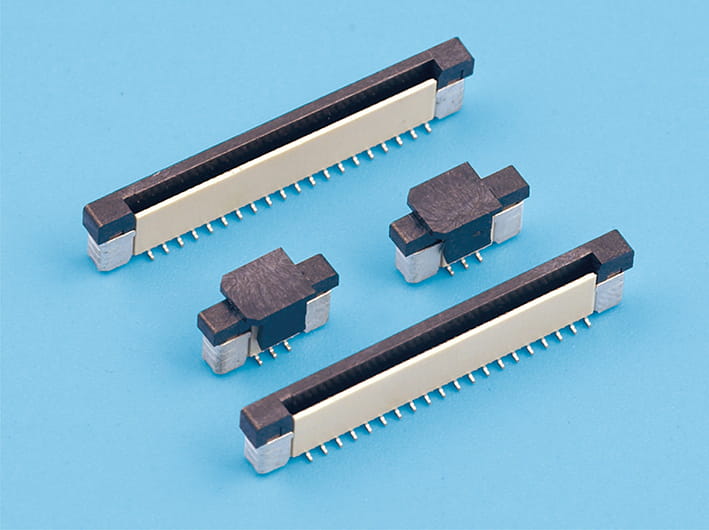

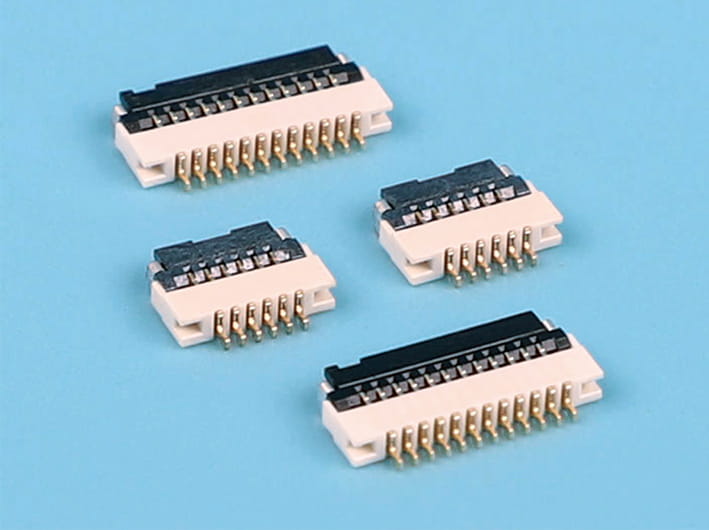

FPC FFC connectors are designed to connect flexible circuits to printed circuit boards (PCBs). The 6 pin FPC cable is often used in smaller devices, while the 40 pin FPC cable is employed for larger, more complex systems. FPC connectors are known for their adaptability and are ideal for applications where space is limited but performance is crucial. FFC connectors, on the other hand, are typically used in flat cable configurations requiring less flexibility.

Choosing the right connector is vital to ensure good performance. For example, a 6 pin FPC cable might be appropriate for smaller applications, while a 40 pin FPC cable is suited for more complex systems.

Steps for Installing FPC FFC Connectors

1. Prepare the Cable and Connector

Before installation, ensure the cable is free of dust and damage. Clean cables, such as the 6 pin FPC cable, can prevent poor connections. Always check for any visible wear before proceeding.

2. Align the Cable Correctly

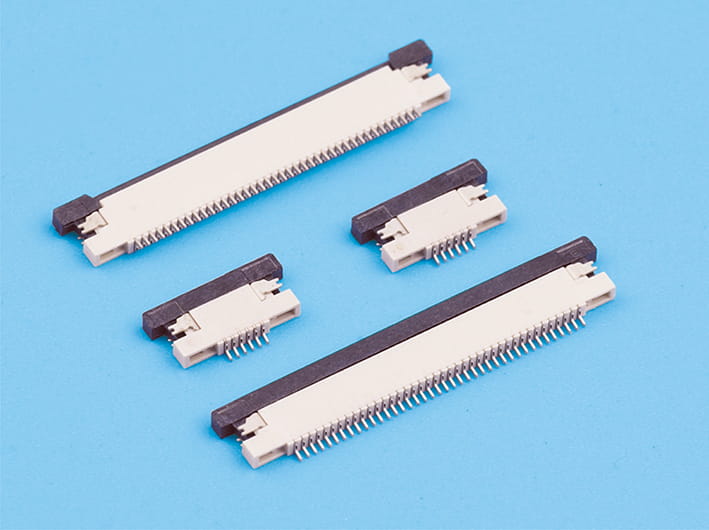

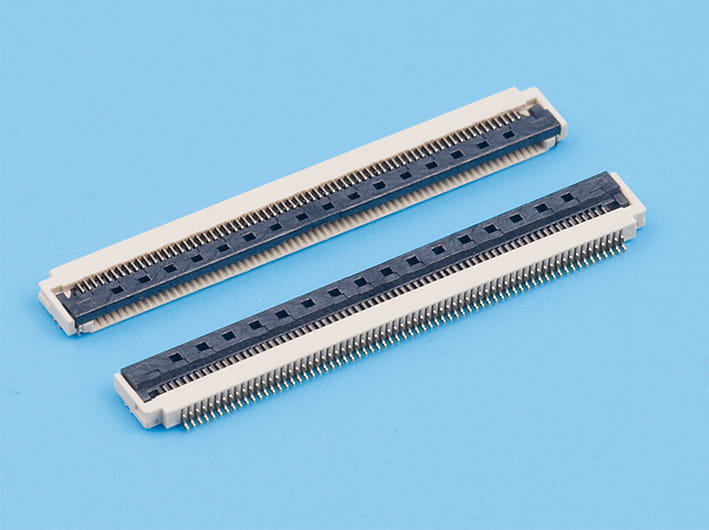

Proper alignment of the FPC FFC connector with the cable is crucial. For instance, aligning the 40 pin FPC cable ensures that the pins make proper contact with the traces on the flexible circuit. Misalignment can cause unreliable connections.

3. Insert the Cable into the Connector

Gently insert the cable into the FPC FFC connector slot, applying even pressure. This ensures the cable is fully seated without causing damage. Avoid forcing the cable into the connector to prevent unnecessary strain.

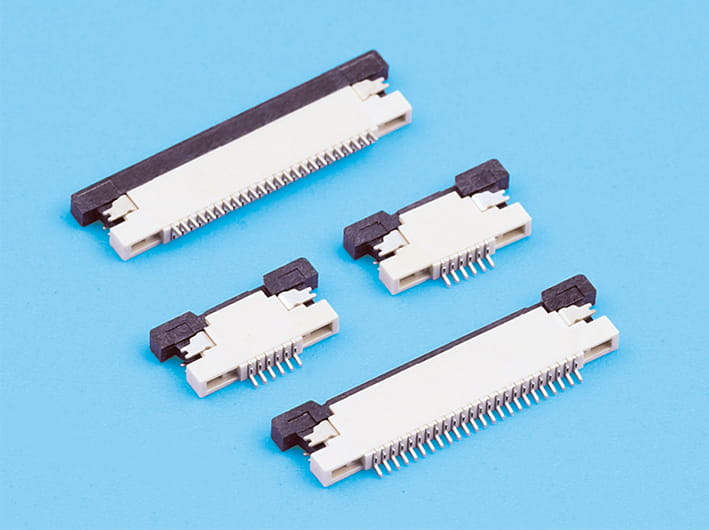

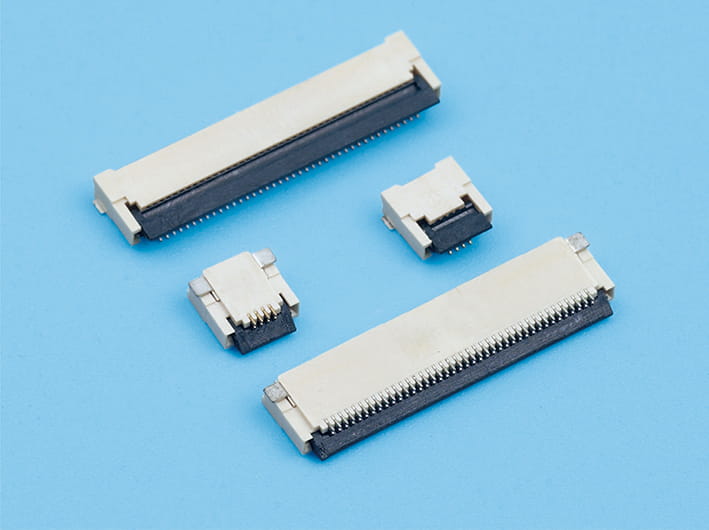

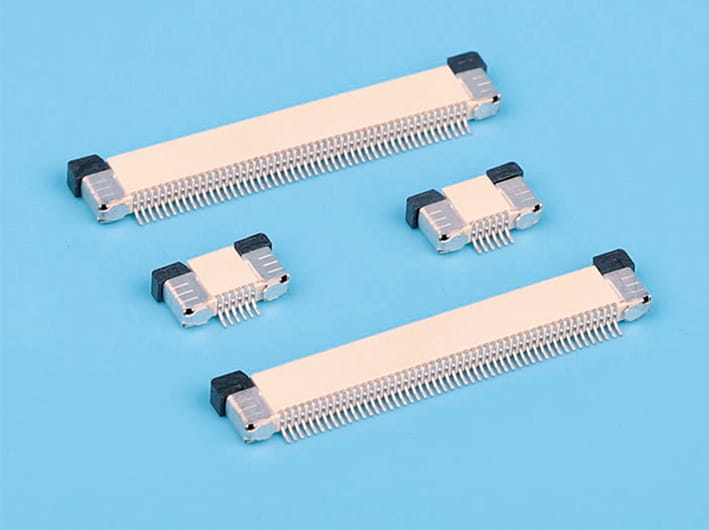

4. Lock the Connector

Many FPC FFC connectors have a locking mechanism, like a latch, to secure the cable in place. Once the cable is inserted, engage the lock to prevent accidental disconnections during use, especially when dealing with larger connectors like the 40 pin FPC cable.

5. Test the Connection

After installation, test the connection to ensure everything is functioning correctly. This may involve checking power or data transmission. Use diagnostic tools to identify any potential issues.

Maintaining FPC FFC Connectors

1. Regular Inspections

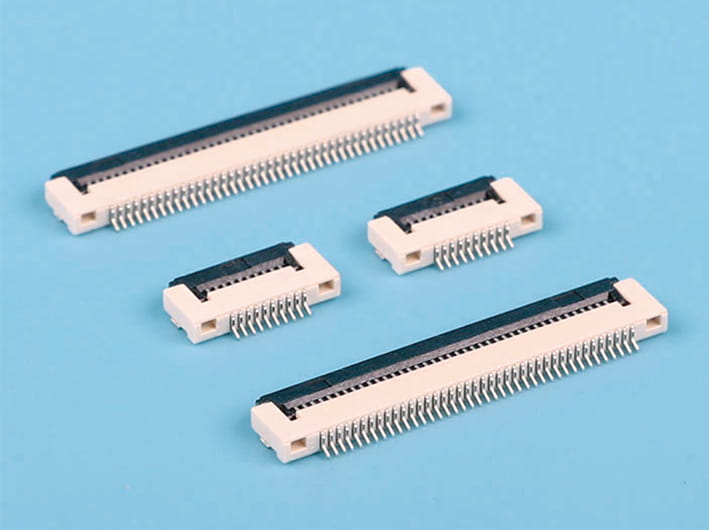

Periodically inspect connectors for wear or damage, particularly on cables like the 6 pin FPC cable and 40 pin FPC cable. Check for physical defects that could affect the connection quality.

2. Keep Connectors Clean

Dust and debris can accumulate on connectors, affecting performance. Use compressed air or a soft brush to clean FPC FFC connectors regularly, avoiding harsh chemicals that could damage the cable or connector.

3. Avoid Overstress

Excessive bending or tension on the cable can cause wear. Ensure cables are routed properly and avoid sharp corners that might cause stress or pinching.

4. Check for Corrosion

If used in harsh environments, inspect for signs of corrosion on the connectors. Corrosion can damage the connection, so using corrosion-resistant connectors may be necessary for some applications.

5. Promptly Replace Damaged Connectors

If a connector becomes damaged or unreliable, replace it immediately to avoid further issues. Delaying replacement can cause more extensive damage to the system.

Proper installation and maintenance of FPC FFC connectors are key to ensuring the performance and longevity of electronic devices. By following the correct installation steps and regularly inspecting connectors, users can prevent common issues and maintain reliable, high-performance connections. Whether working with a 6 pin FPC cable or a 40 pin FPC cable, following these practices ensures your electronic systems remain functional and efficient.

English

English 中文简体

中文简体 Español

Español عربى

عربى