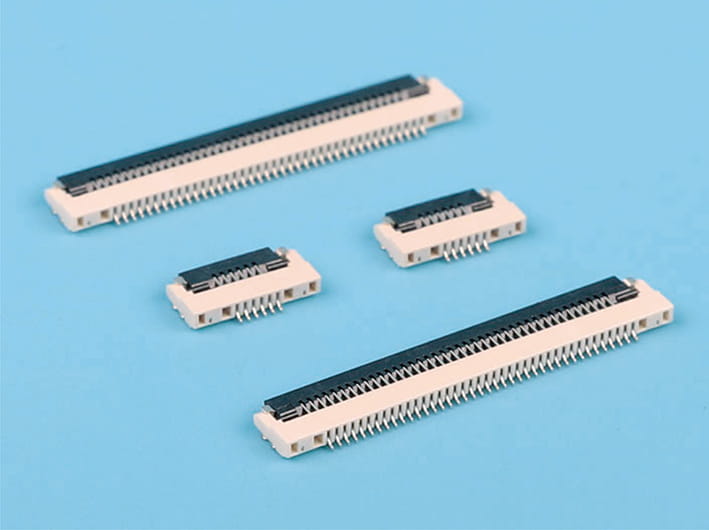

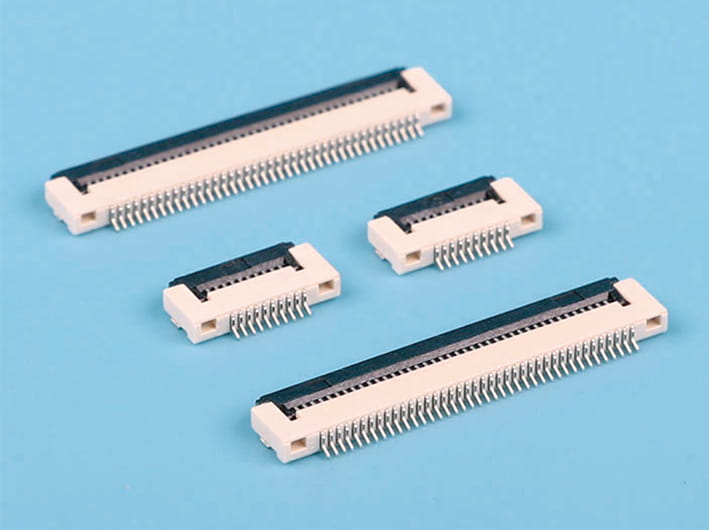

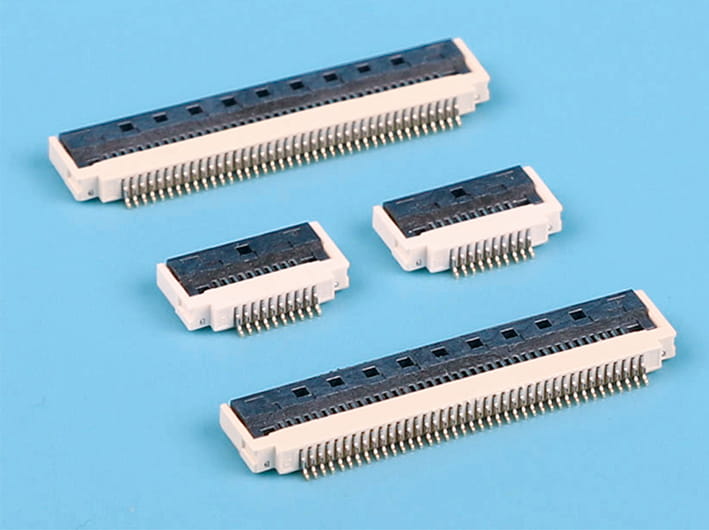

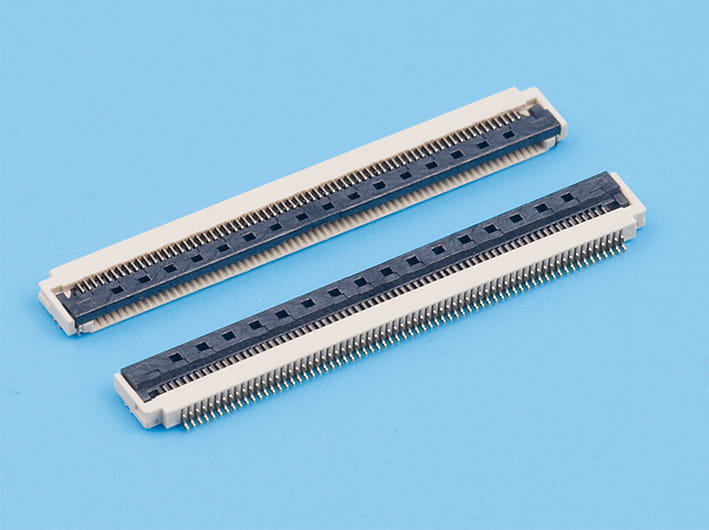

Electronic Component Connectors: What to Look for in Quality and Durability?

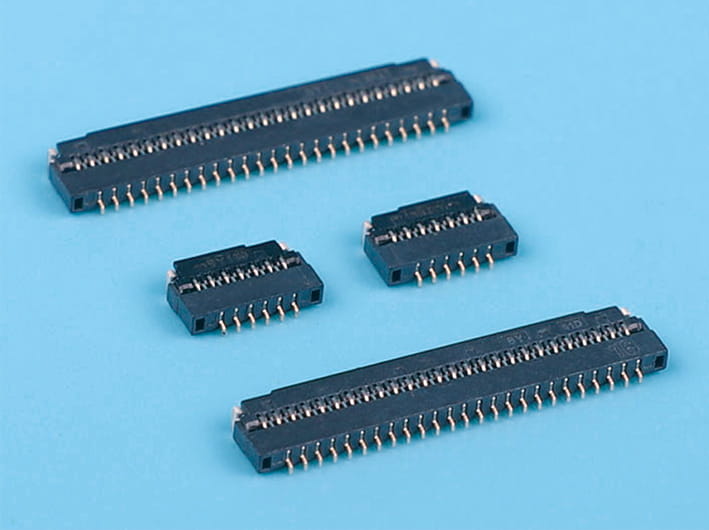

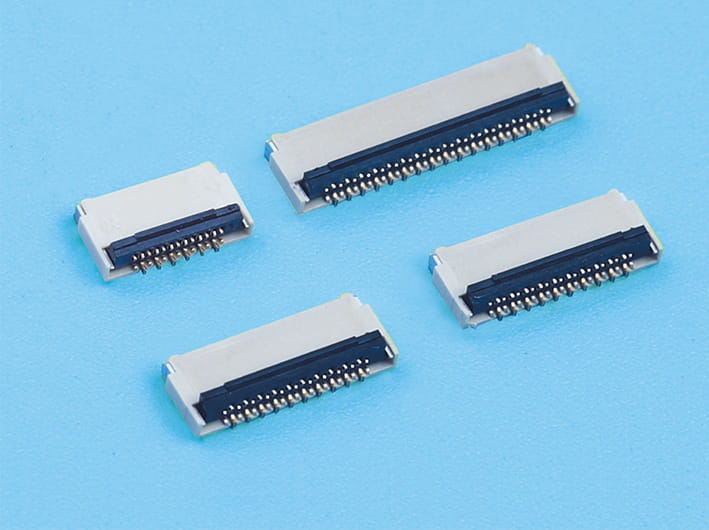

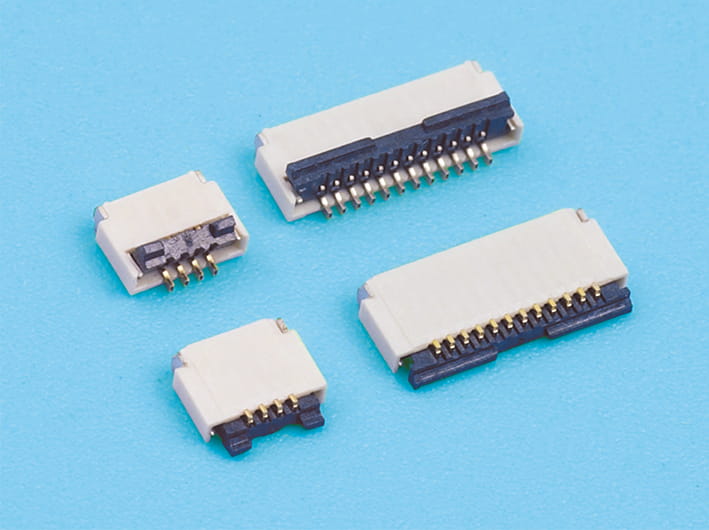

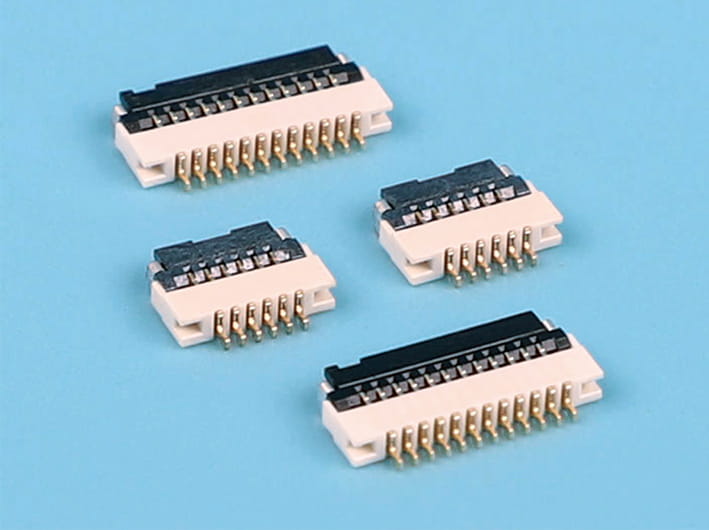

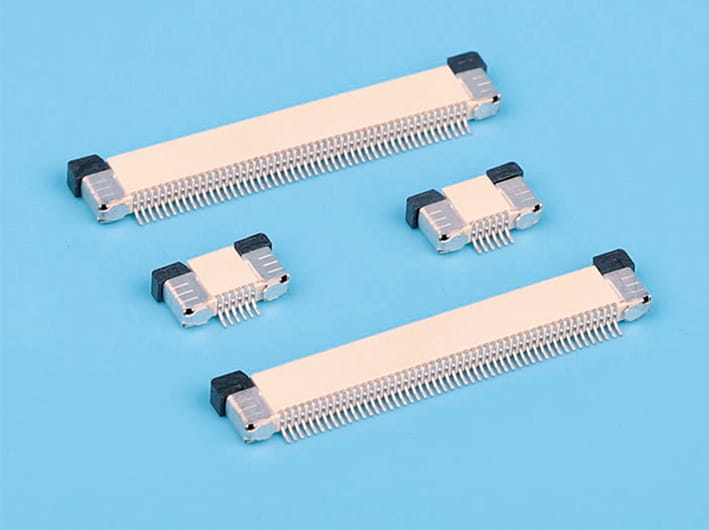

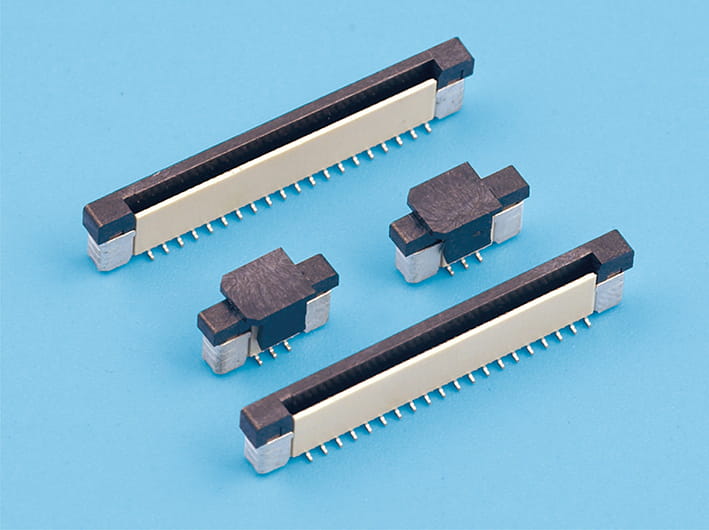

When dealing with electronic systems, even minor failures in electronic component connectors can cause significant disruptions. These connectors are responsible for establishing and maintaining critical links within devices, such as circuit boards, sensors, and power supplies. Poor-quality connectors can result in unstable connections, signal losses, or, in cases, device malfunction.

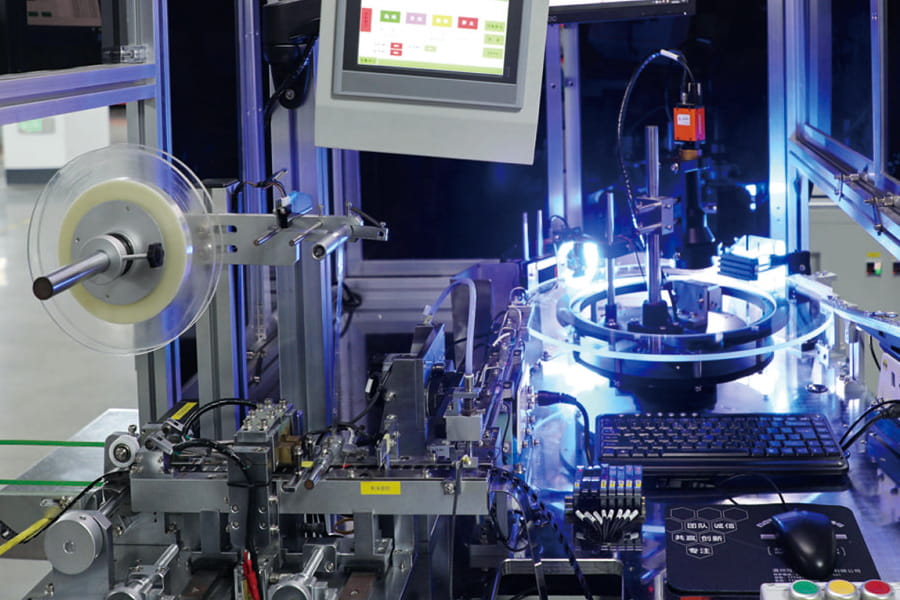

Investing in top-tier electronic component connectors ensures that systems operate efficiently over time, reducing the need for frequent maintenance or replacements. This is particularly crucial in industries such as healthcare, aerospace, and automotive, where reliability is non-negotiable.

Key Features to Look for in Connectors

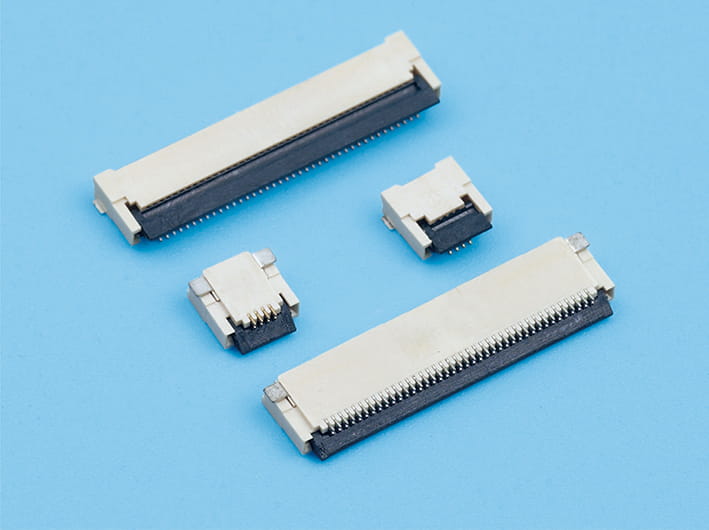

1. Material Durability

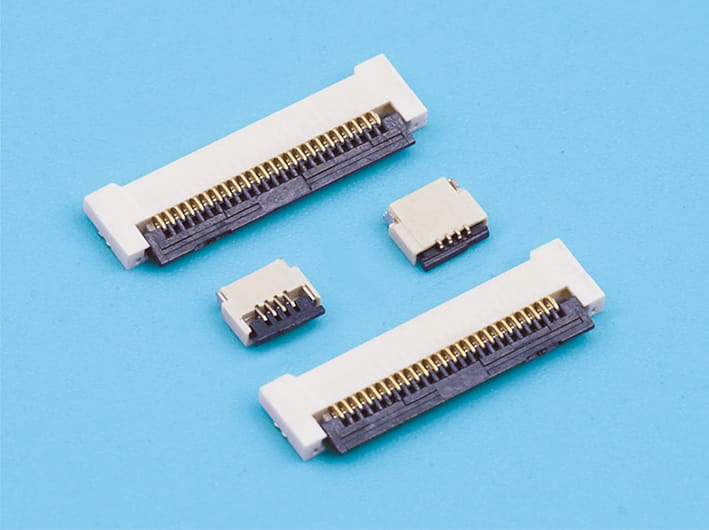

The materials used in electronic component connectors directly affect their longevity and performance. Connectors made from high-grade metals like gold or nickel-plated alloys offer outstanding conductivity and corrosion resistance, making them ideal for harsh environments.

2. Compatibility with Electronic Connecting Wires

Selecting connectors that align with the specifications of the electronic connecting wire is essential. The wire's size, material, and current-carrying capacity should match the connector to ensure a seamless connection.

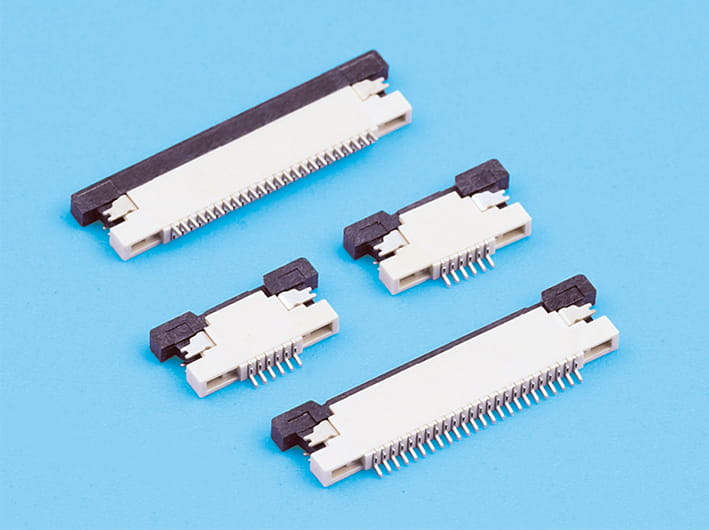

3. Ease of Assembly

High-quality connectors should be easy to assemble and disassemble. This not only simplifies installation but also makes maintenance and repairs more straightforward.

4. Resistance to Environmental Stress

For devices exposed to temperatures, moisture, or vibrations, connectors with robust environmental resistance are critical. Sealed or waterproof electronic component connectors are commonly used in outdoor or industrial applications.

5. Signal Integrity

Modern electronic devices require connectors that minimize interference and ensure signal integrity. Proper shielding within connectors can prevent electromagnetic interference (EMI) and ensure stable performance.

Applications of Electronic Component Connectors

The versatility of electronic component connectors makes them indispensable in various sectors:

- Consumer Electronics: Smartphones, tablets, and laptops rely on compact connectors to deliver power and data across intricate circuits.

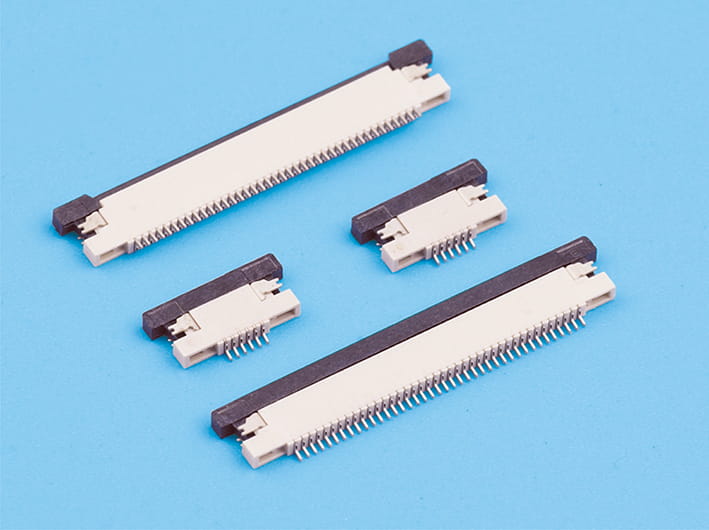

- Automotive Systems: Vehicles use durable connectors to link sensors, control modules, and power systems, ensuring safety and functionality.

- Industrial Equipment: Heavy machinery and automated systems use rugged connectors to withstand demanding conditions.

- Medical Devices: Life-saving equipment, such as imaging machines and portable monitors, depend on reliable connections for precision and efficiency.

Role of Electronic Connecting Wires in Connector Performance

While the connectors themselves are crucial, the performance of electronic connecting wires also plays a significant role. These wires transmit electrical signals between components and work in tandem with connectors to ensure stable communication.

High-quality electronic connecting wires are designed to handle specific voltage and current levels while maintaining flexibility and durability. Using subpar wires can compromise the performance of even connectors, highlighting the need for compatibility and quality in both components.

Tips for Choosing the Right Connectors

1. Define Application Requirements: Identify the specific needs of your device or system, such as voltage capacity, environmental conditions, and size constraints.

2. Prioritize Reliability: Look for manufacturers with a proven track record of producing high-quality electronic component connectors and electronic connecting wires.

3. Consider Future Scalability: Select connectors that allow for upgrades or expansions to accommodate technological advancements.

4. Evaluate Cost vs. Performance: While cost is a factor, prioritize performance and durability to avoid long-expenses related to repairs or replacements.

High-quality electronic component connectors and compatible electronic connecting wires are the foundation of reliable electronic systems. By prioritizing materials, compatibility, and environmental resistance, manufacturers can ensure that their products deliver durability and performance over time.

English

English 中文简体

中文简体 Español

Español عربى

عربى