Choosing the Right Micro Board to Board Connector for Your Project

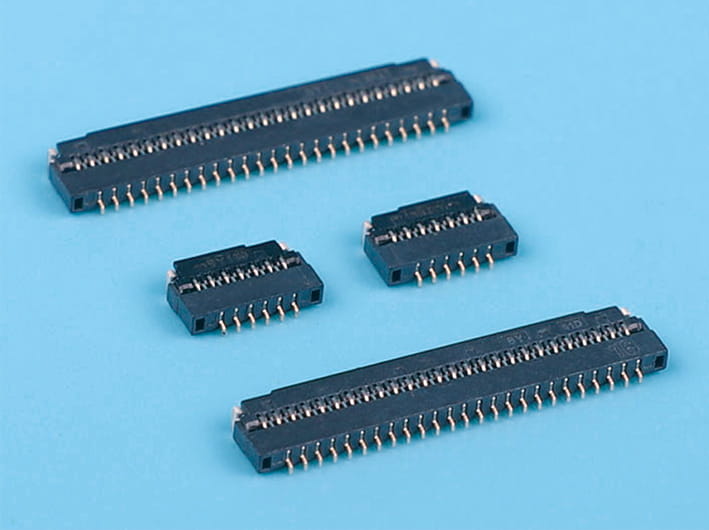

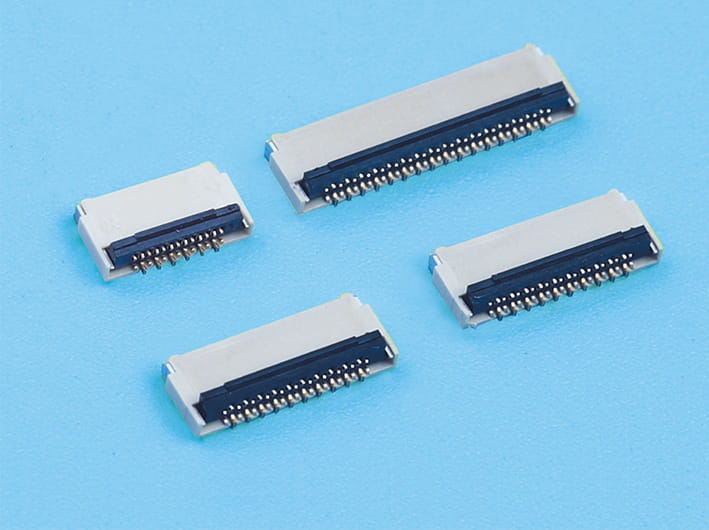

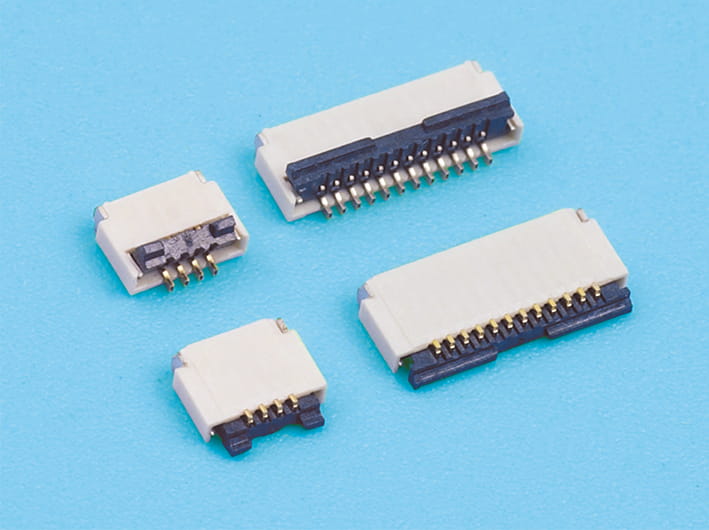

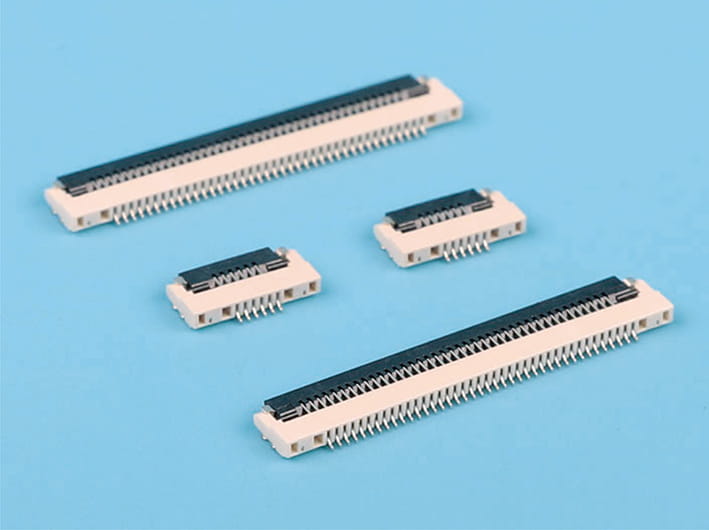

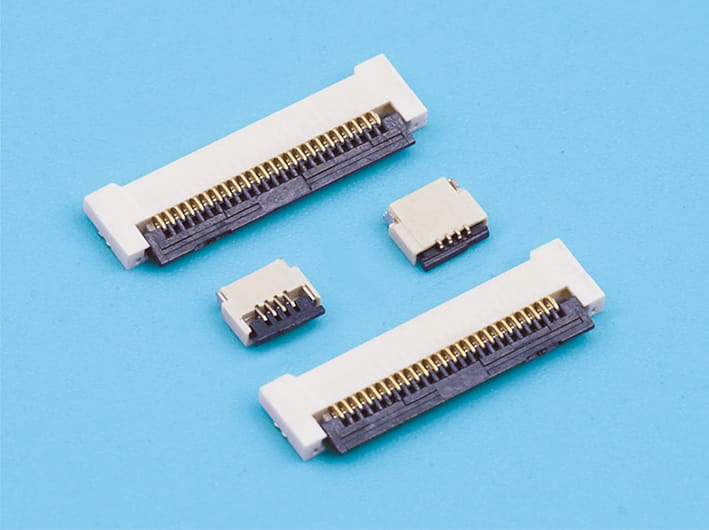

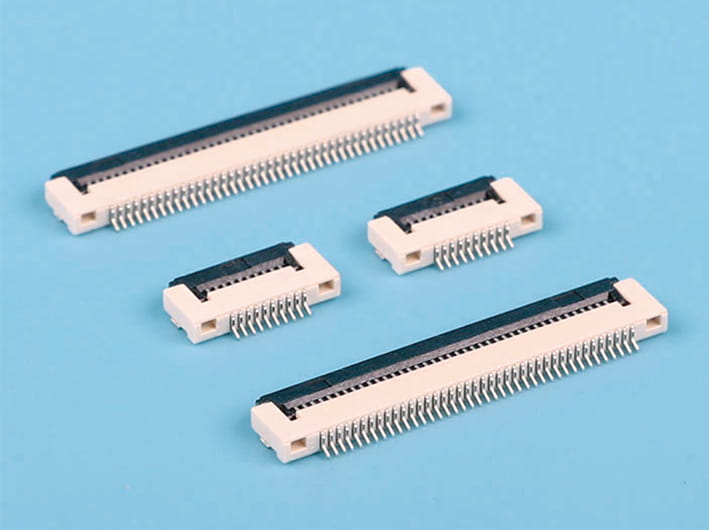

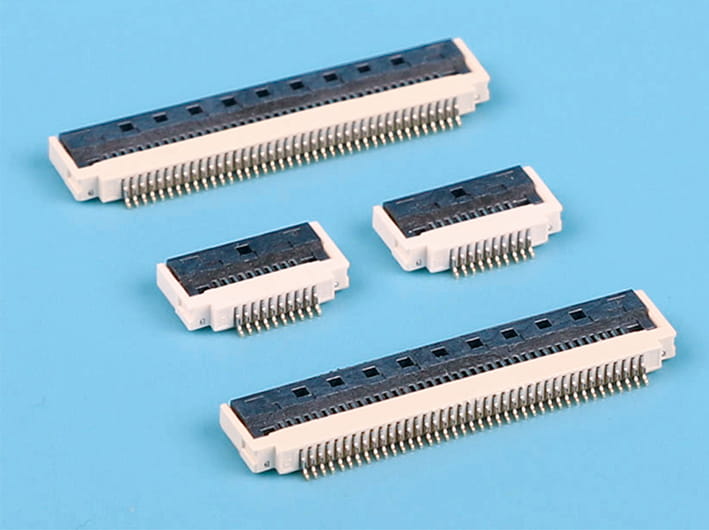

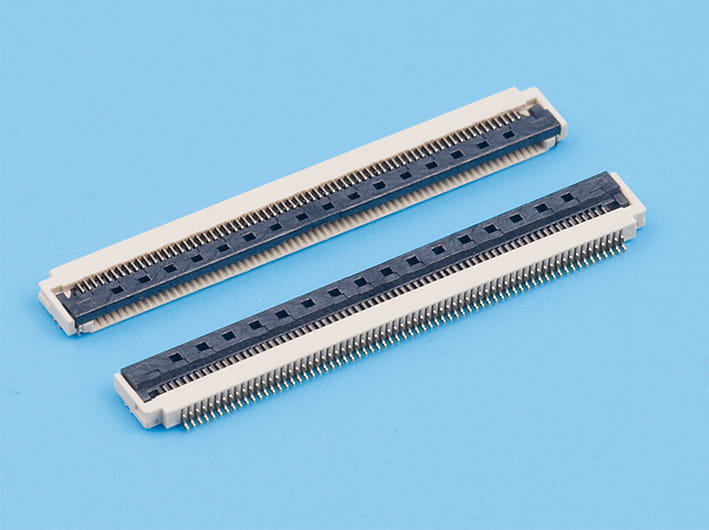

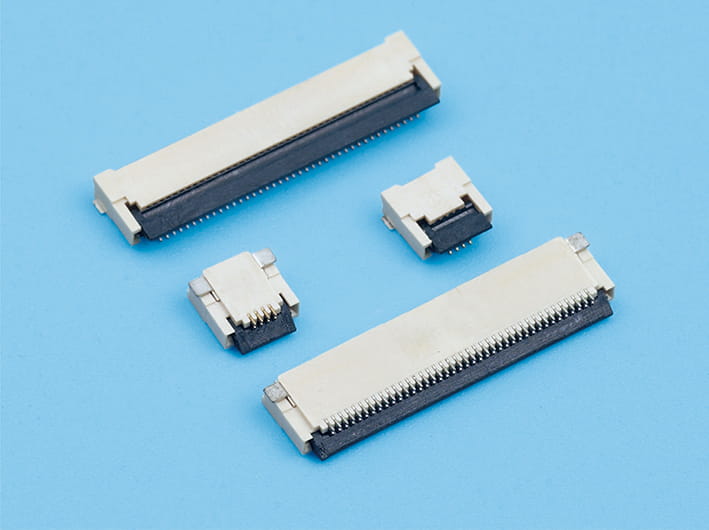

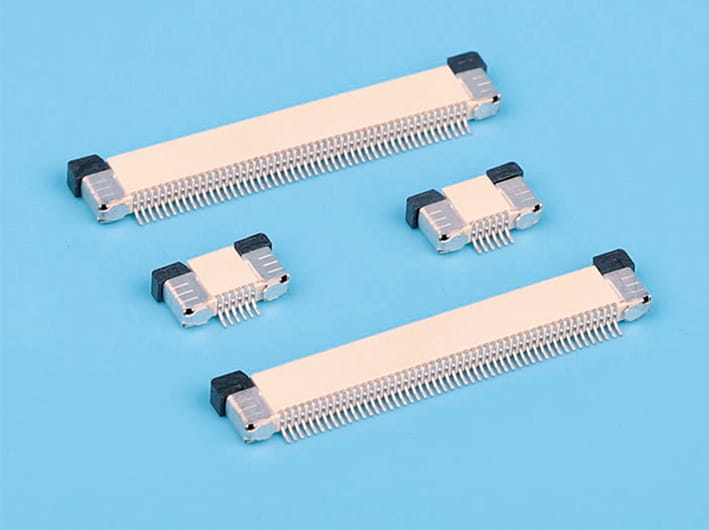

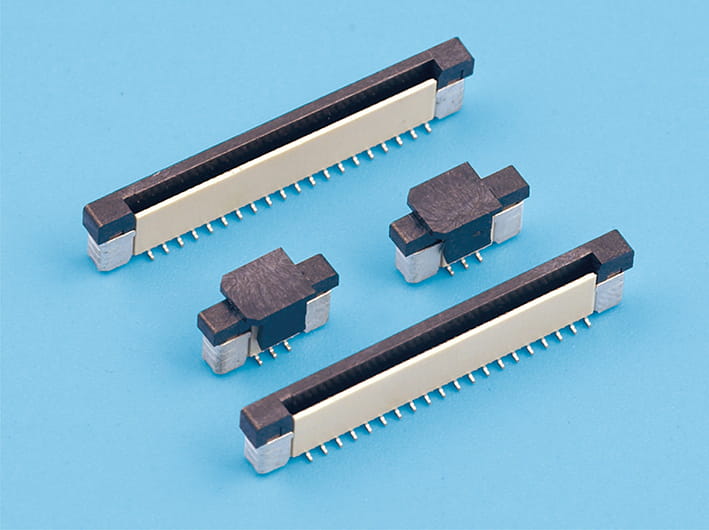

Micro board to board connectors are essential in compact electronic devices where space is limited but high-density interconnections are necessary. These connectors allow for the transmission of both power and signals between two PCBs (Printed Circuit Boards) within a single system. A micro board to board connector typically has a smaller pitch, which helps reduce the overall footprint of the device, making it ideal for smartphones, wearables, medical devices, and other compact systems.

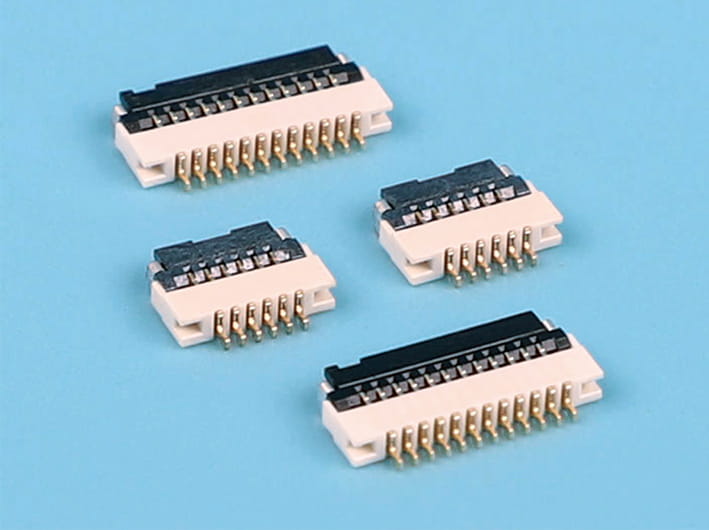

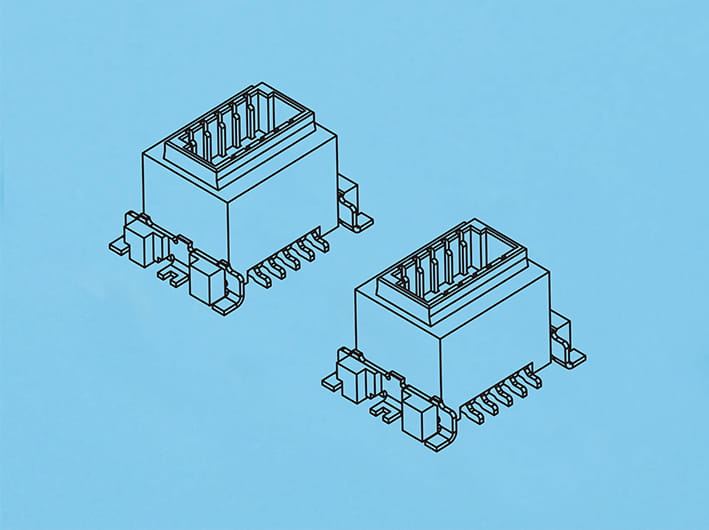

In contrast, PCB board to board connectors are used for larger, industrial applications where the boards are somewhat bigger but still require efficient interconnection. The primary difference between the two types of connectors lies in their size, density, and the complexity of the application they're designed for.

Factors to Consider When Choosing a Micro Board to Board Connector

1. Space Constraints

One of things to consider when selecting a micro board to board connector is the space available on the PCB. Micro connectors are typically used when there's limited space, as they allow for higher-density connections without increasing the overall size of the device. If your project requires a connector for a compact design, this type is the ideal choice. The smaller pitch of a micro board to board connector helps save precious space on the PCB.

2. Signal Integrity and Performance

Another important factor to consider is the integrity of the signal transmission. PCB board to board connectors are designed to handle high-frequency signals, but micro connectors must ensure that they maintain the integrity of these signals in compact spaces. Micro connectors can be designed to support high-speed data transmission, making them suitable for devices that rely on minimal interference, such as high-performance computers or communication devices.

3. Power Handling Capacity

Power handling is another key consideration. Some micro board to board connectors are specifically designed to transmit power as well as signals. Depending on your project's requirements, you need to choose a connector that can handle the power requirements of your device. Some projects may involve low-power devices, while others, like consumer electronics or robotics, may require connectors that can support higher power levels.

4. Durability and Reliability

For many projects, particularly those in industrial or medical applications, the durability and reliability of the connectors are paramount. PCB board to board connectors often need to withstand harsh conditions, including vibrations, high temperatures, and moisture. When selecting a micro board to board connector, ensure that it's rated for the environmental conditions in which your device will operate. This ensures that the connector will perform goodly and last longer.

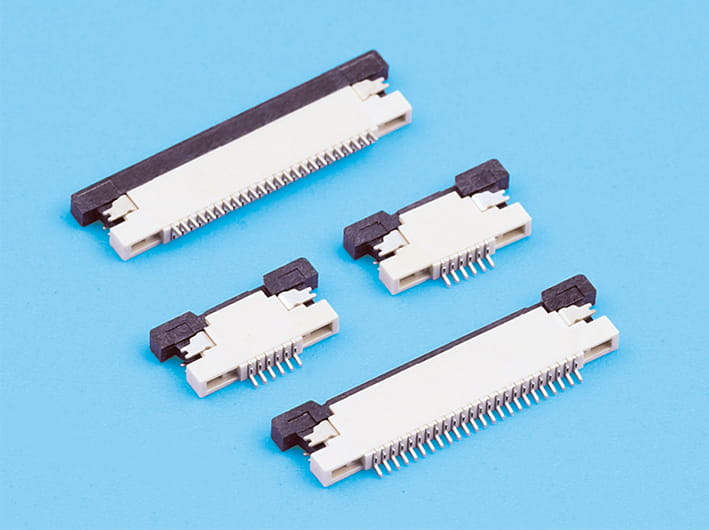

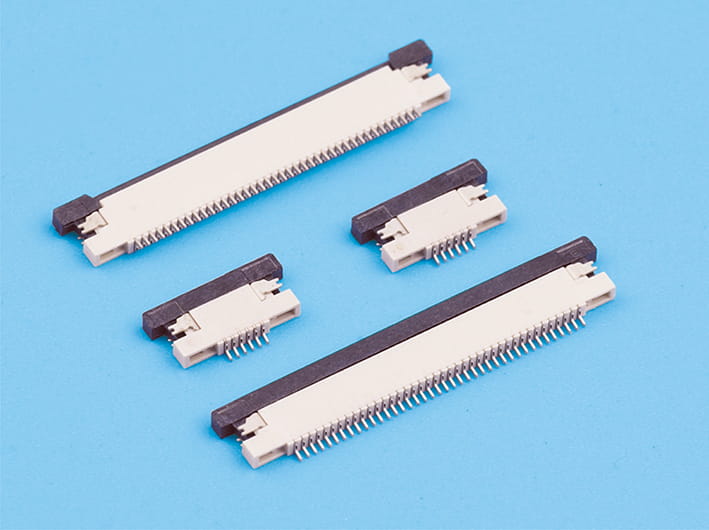

5. Connector Type and Pitch

The type of micro connector you select depends on your application. Different micro board to board connectors come in various pitches, such as 0.5mm, 0.8mm, or 1.0mm. The smaller the pitch, the higher the density of the connector, but it can also make it more challenging to solder and maintain. The pitch you choose should align with the pin count, signal integrity requirements, and power handling needed for your project.

6. Ease of Assembly and Maintenance

While micro connectors are compact, they can be tricky to assemble due to their small size. PCB board to board connectors generally have more robust designs, making them easier to handle and assemble. If your project involves a production line with high volumes of devices, it may be better to choose connectors that are easier to assemble and maintain. On the other hand, if you are designing a product with fewer units but tighter space constraints, a micro board to board connector will likely be the better fit.

Selecting the right micro board to board connector for your project is a critical decision that depends on various factors, including space constraints, signal integrity, power handling, and durability. These connectors are essential for enabling high-density interconnectivity in modern electronics, making them ideal for a wide range of applications, from consumer electronics to industrial systems.

English

English 中文简体

中文简体 Español

Español عربى

عربى