Applications of Flat Flexible Connectors in Automotive Circuit Systems

The Rise of Flat Flexible Connectors in Automotive Electronics

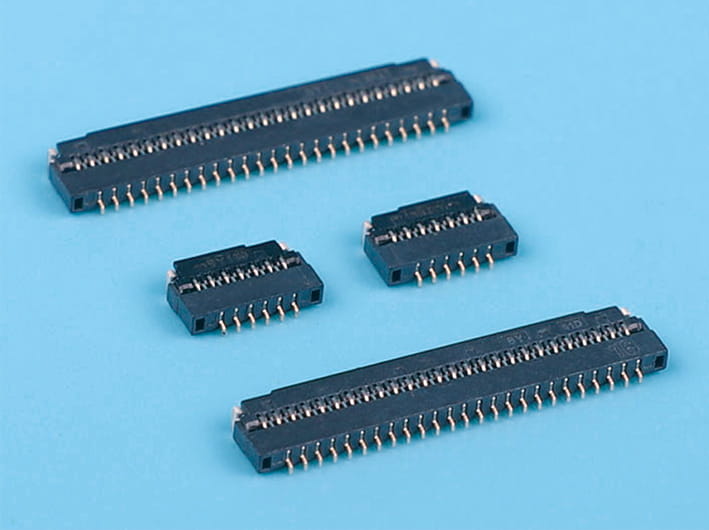

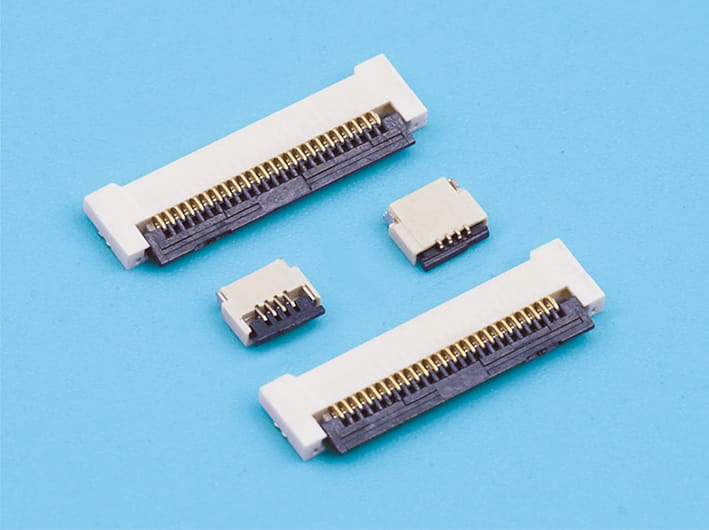

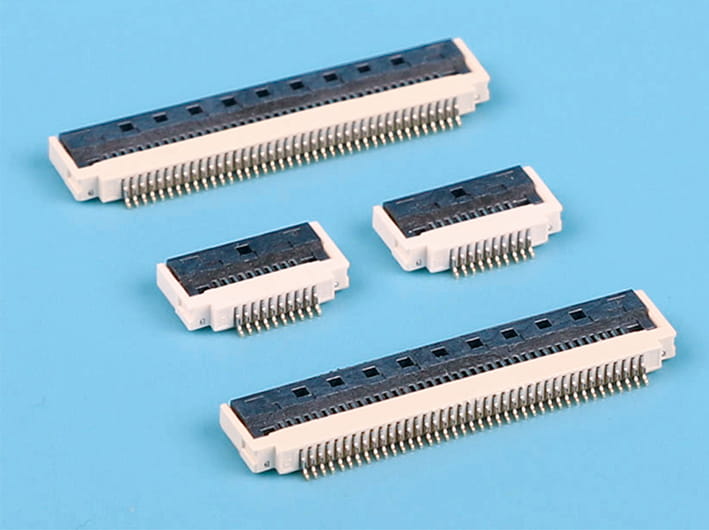

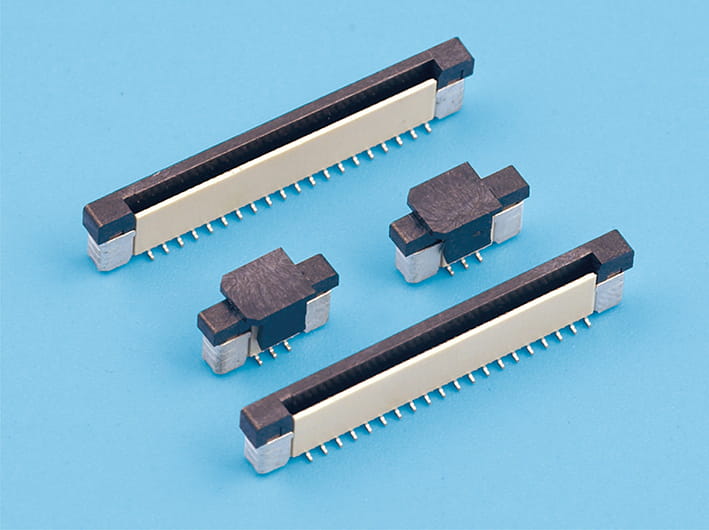

Automotive manufacturers are constantly striving to reduce the size and weight of electronic components while maintaining or improving performance. Flat flexible connectors are an ideal solution to this challenge, offering a compact form factor without sacrificing electrical integrity. These connectors are widely used in automotive wiring systems, where space is limited, and complex circuits need to be streamlined. In such systems, flat terminal connectors are crucial for connecting various components like sensors, switches, and modules that need to operate seamlessly within the vehicle.

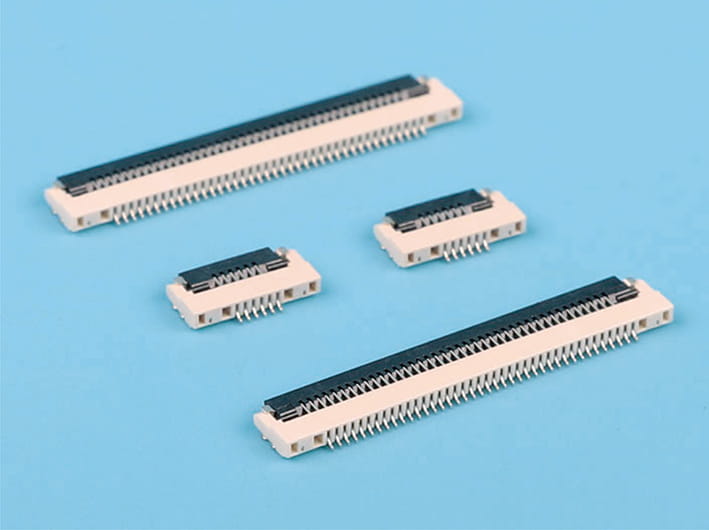

The unique design of flat flexible connectors makes them particularly well-suited for automotive applications, as they can be easily routed through tight spaces, often alongside other components in the vehicle's wiring harness. This ensures that there is minimal disruption to the overall design of the vehicle, improving both aesthetics and functionality. The ability of these connectors to provide multiple contact points along a single flat surface helps improve the efficiency of the electrical connections, ensuring both robust power delivery and data transfer capabilities.

Enhanced Durability in Automotive Environments

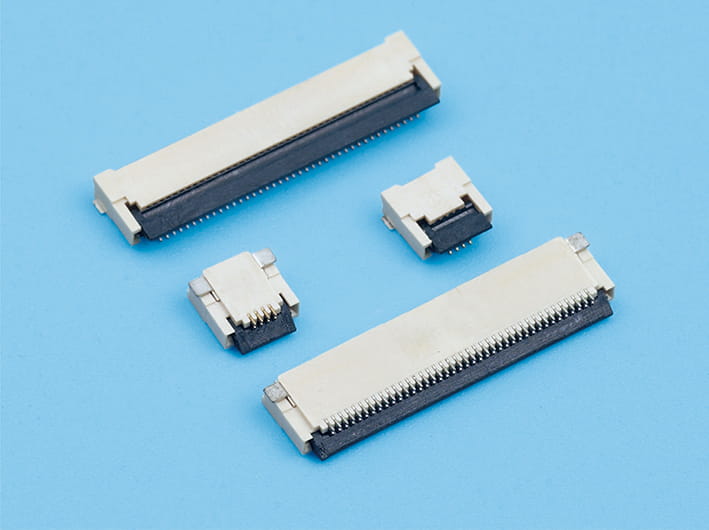

Automotive environments can be harsh, with components subject to high temperatures, vibration, moisture, and other demanding conditions. This makes the selection of the right connectors critical for ensuring the longevity and reliability of the system. Flat terminal connectors and flat flexible connectors are designed to withstand these challenges, making them ideal for use in automotive applications.

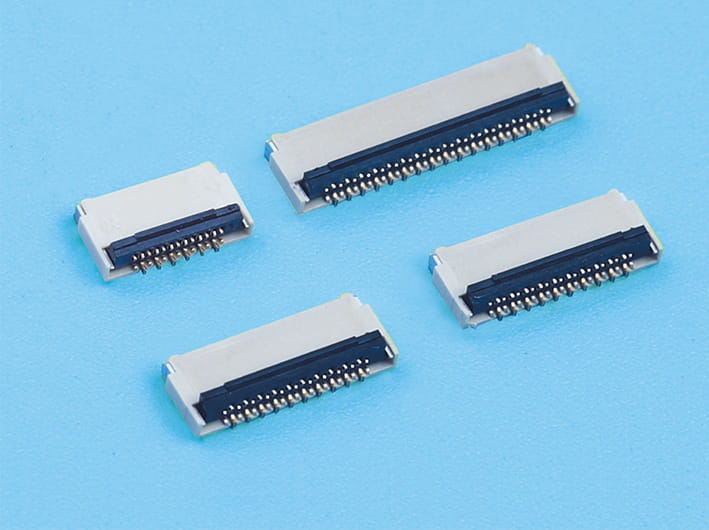

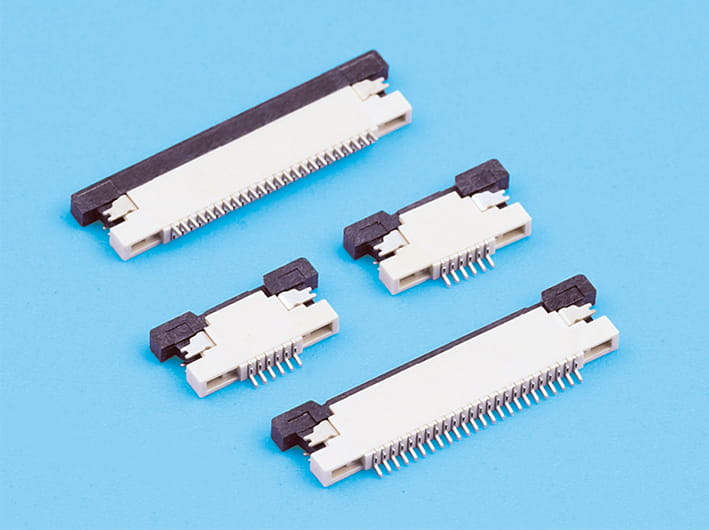

For example, flatcable connectors are often used in automotive power distribution units, where they are exposed to fluctuating temperatures and high electrical loads. Their design ensures a secure and stable connection, even in conditions. Furthermore, flat flexible connectors are frequently employed in areas such as lighting systems, sensors, and electronic control units (ECUs), where flexibility and durability are key. They help to reduce the need for bulky connectors and wiring, which can cause complications in routing and assembly.

Reducing Wiring Complexity

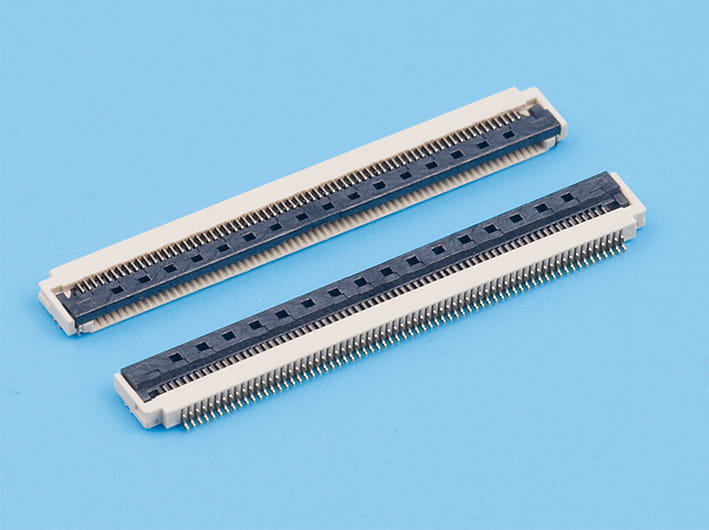

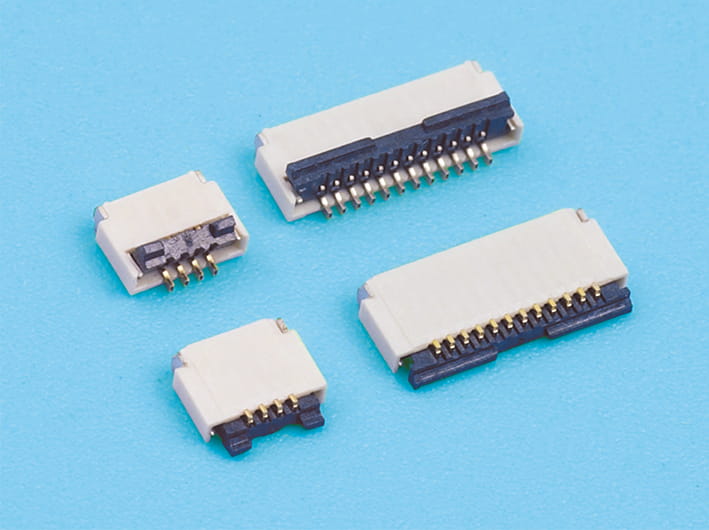

The automotive industry is increasingly adopting more complex electrical systems, especially with the rise of electric vehicles (EVs) and hybrid models. Flatcable connectors offer a streamlined solution to manage the complex wiring systems required for these modern vehicles. By using flat flexible connectors, manufacturers can reduce the overall bulk of wiring harnesses, making them easier to install and maintain.

In hybrid and electric vehicles, flat terminal connectors play a significant role in efficiently connecting the high-voltage battery system to the vehicle's powertrain. These connectors ensure that electrical signals and power are transferred safely and reliably between components, minimizing the risk of electrical failure. The space-saving design of flatcable connectors also contributes to the vehicle's overall weight reduction, an important factor in enhancing fuel efficiency and battery life.

Integration with Advanced Automotive Systems

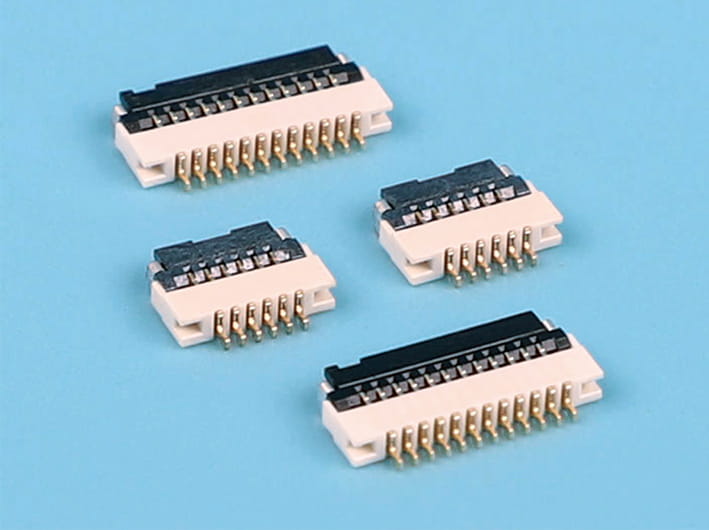

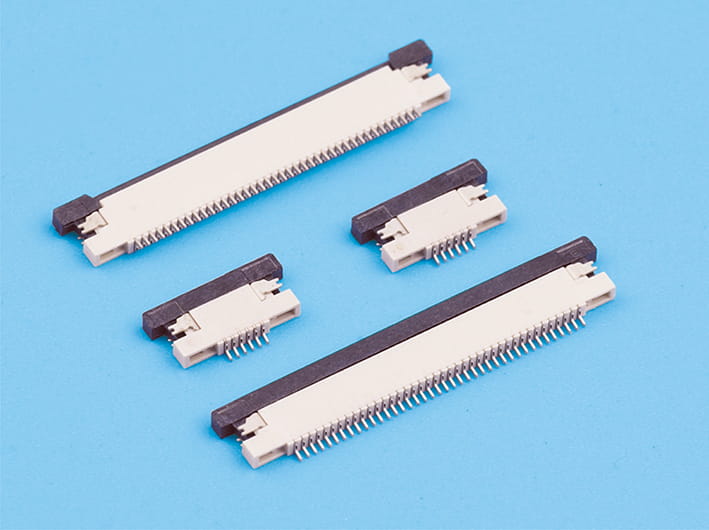

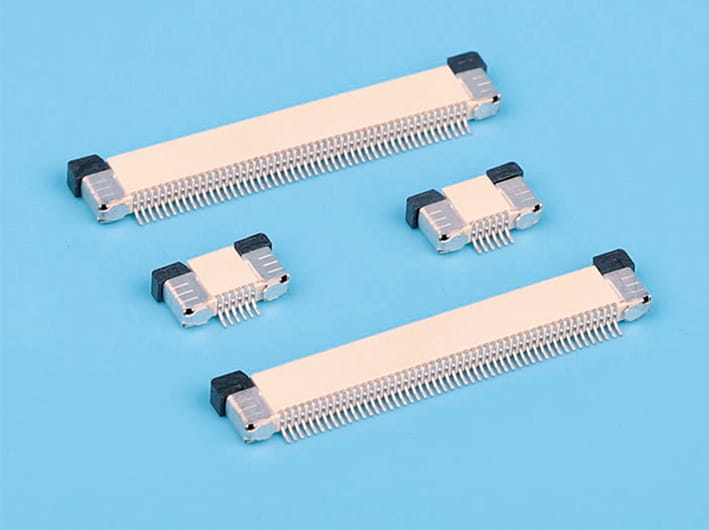

As the automotive industry moves toward more sophisticated systems, including autonomous vehicles and connected car technologies, the role of flat flexible connectors becomes even more critical. Flat terminal connectors and flatcable connectors are essential in linking various sub-systems within the vehicle, such as the powertrain, infotainment, and sensor networks.

For instance, flat flexible connectors are increasingly used in advanced driver-assistance systems (ADAS), where multiple sensors such as cameras, radar, and LiDAR must be interconnected to provide real-time data for the vehicle's navigation system. The flexibility and compactness of these connectors allow for easy integration into the tight spaces around the vehicle's chassis, ensuring that the electronics function efficiently without compromising on safety or reliability.

Additionally, flatcable connectors are critical in maintaining the high-speed data transfer required for modern infotainment systems. These connectors support the communication between entertainment units, touch screens, and multimedia devices, allowing for a seamless user experience while driving.

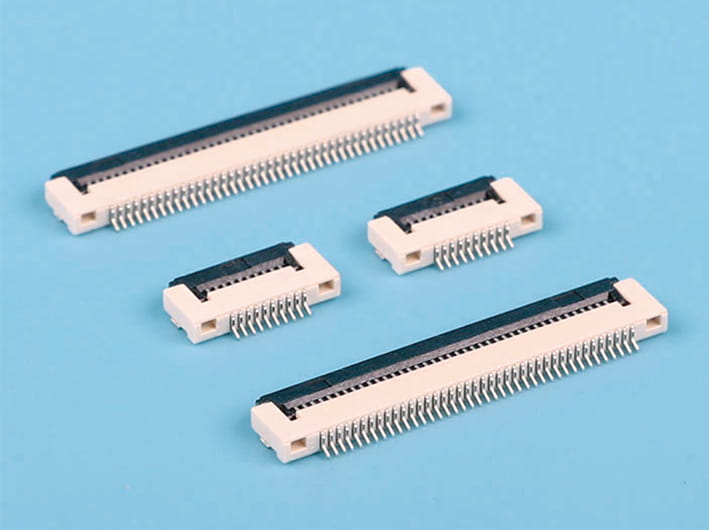

As more automotive systems require fast, secure, and space-efficient wiring solutions, flatcable connectors will continue to serve as a fundamental building block of next-generation automotive circuits. These connectors will help drive the transition toward more compact, efficient, and sustainable vehicles, making them a key component in the automotive industry's future.

English

English 中文简体

中文简体 Español

Español عربى

عربى