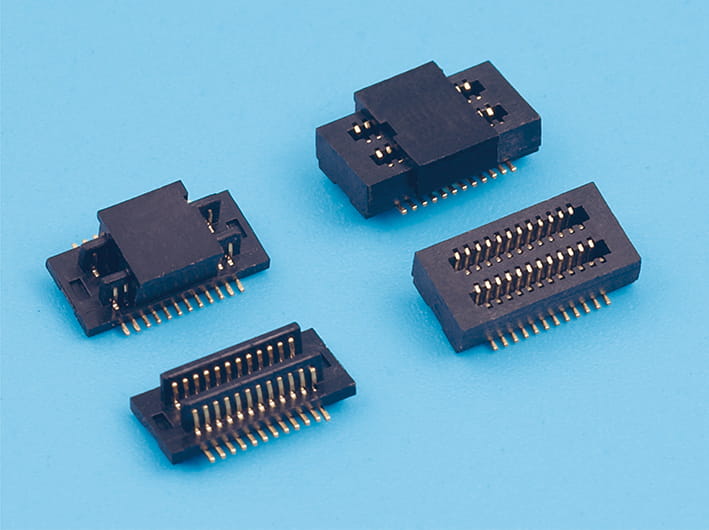

Applications of Automotive Board to Board Connectors in EV Systems

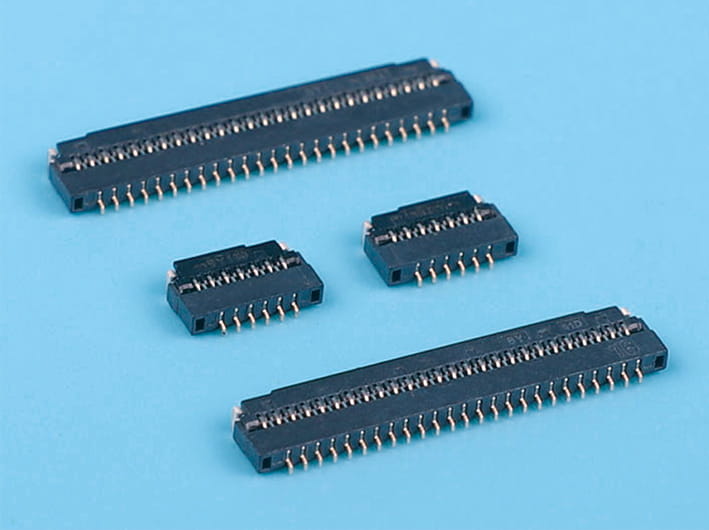

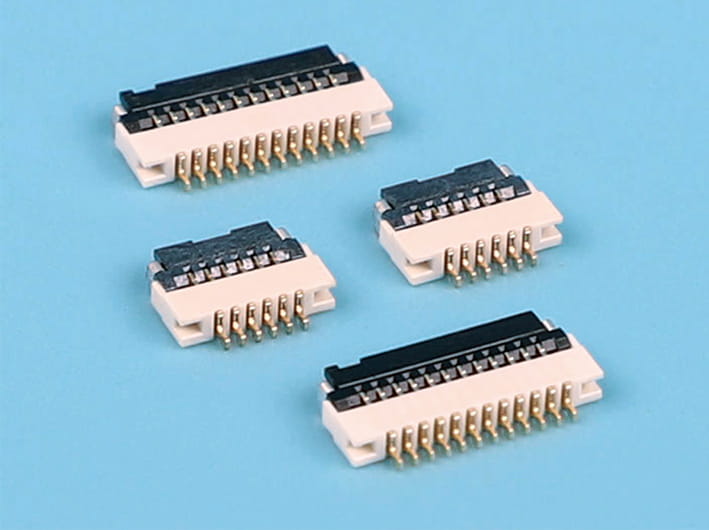

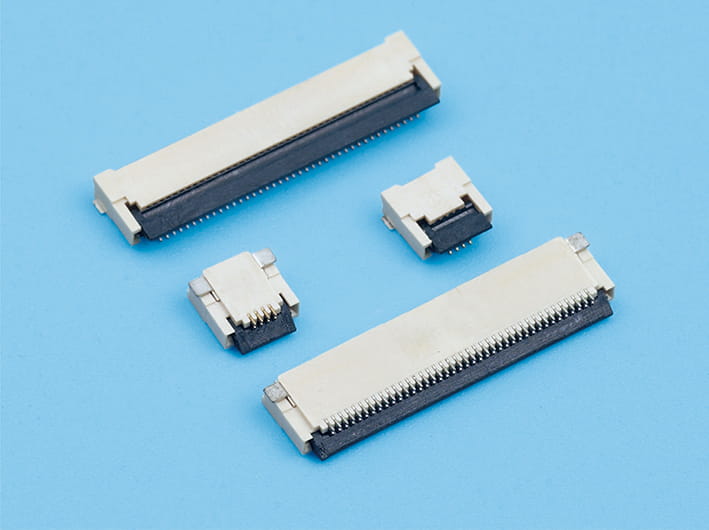

Automotive board to board connectors are designed to connect different parts of an electric vehicle's electrical system, such as powertrain controllers, battery management systems (BMS), charging modules, and infotainment systems. These connectors create a secure electrical connection between two circuit boards, allowing for the smooth transmission of data and power across the vehicle's electronic systems. By connecting various electronic components, automotive board to board connectors help streamline the design of complex systems while ensuring high reliability and durability.

For EV systems, which often involve complex power management, sensor networks, and communication modules, the integrity of these connectors is essential. Poor-quality connectors can cause electrical failures, malfunctioning systems, and potential safety hazards. As such, the automotive board to board connector is designed to meet the stringent demands of the automotive industry, with high resistance to vibration, thermal fluctuations, and environmental stressors.

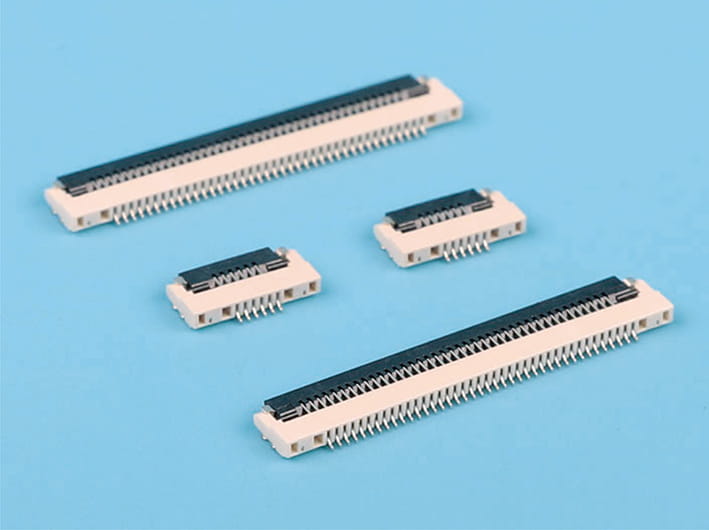

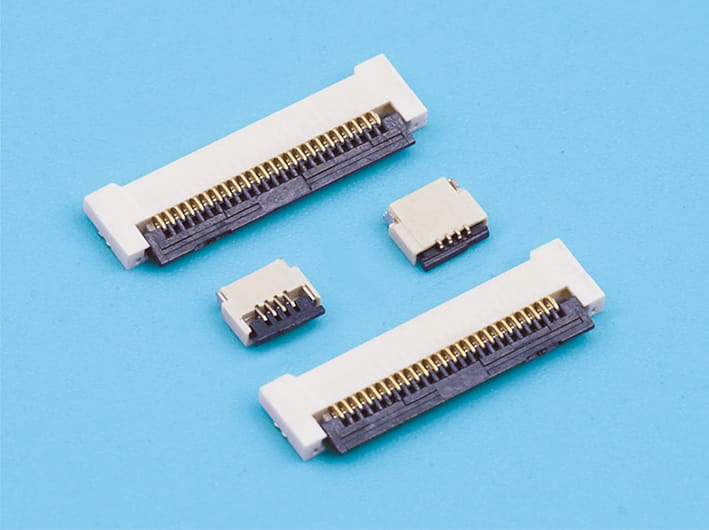

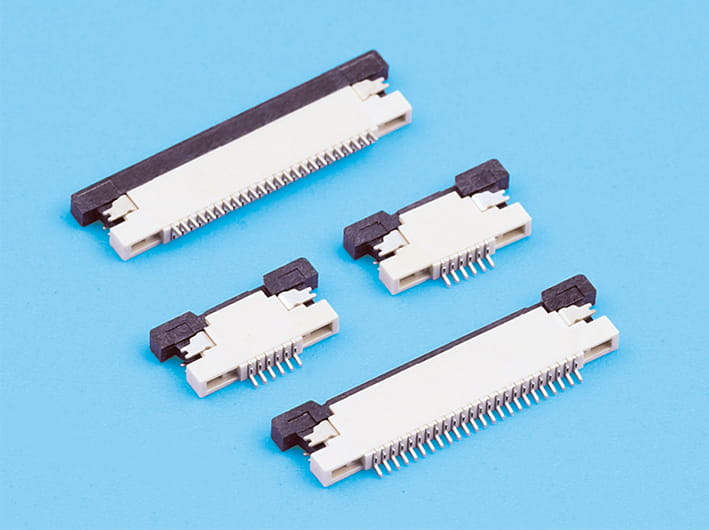

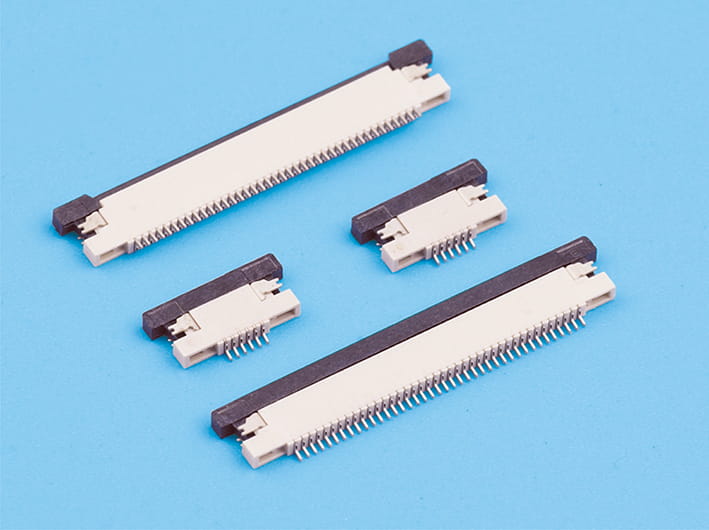

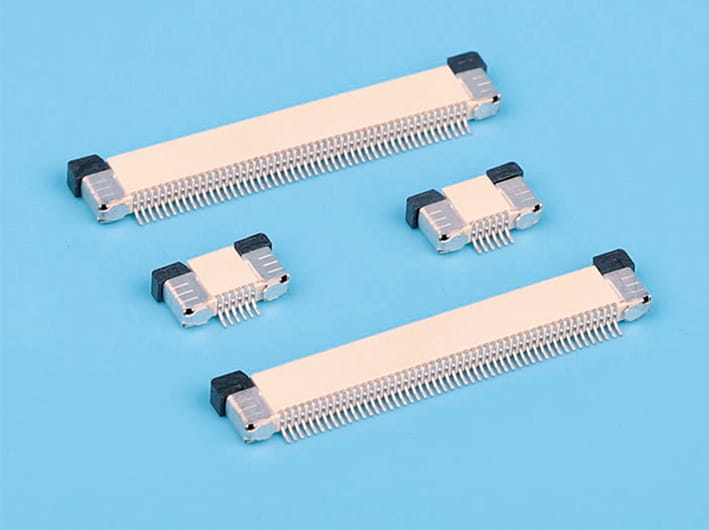

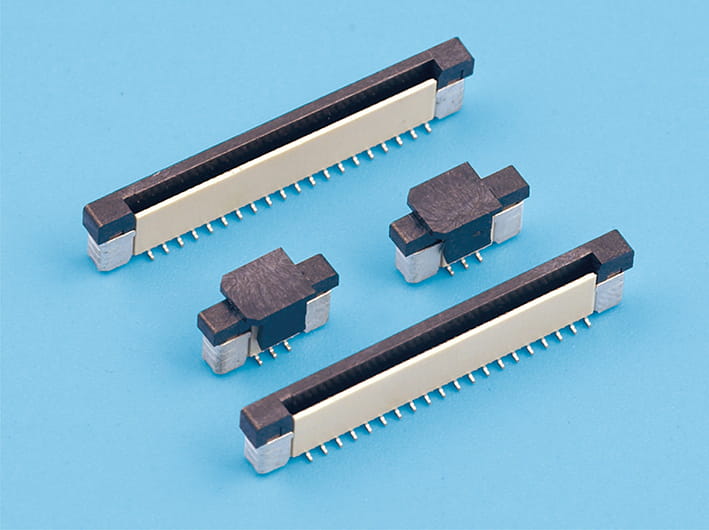

FPC to Board Connectors in EV Applications

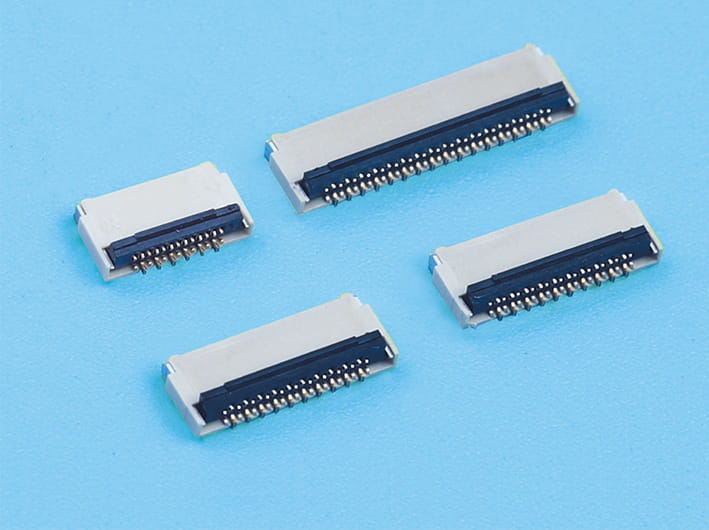

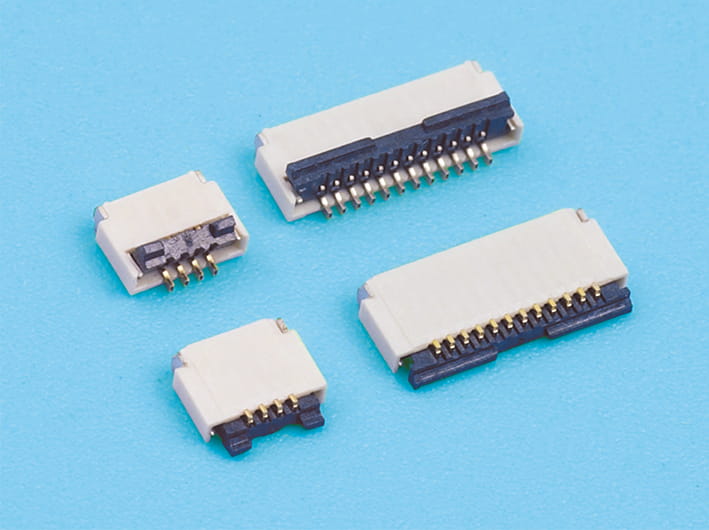

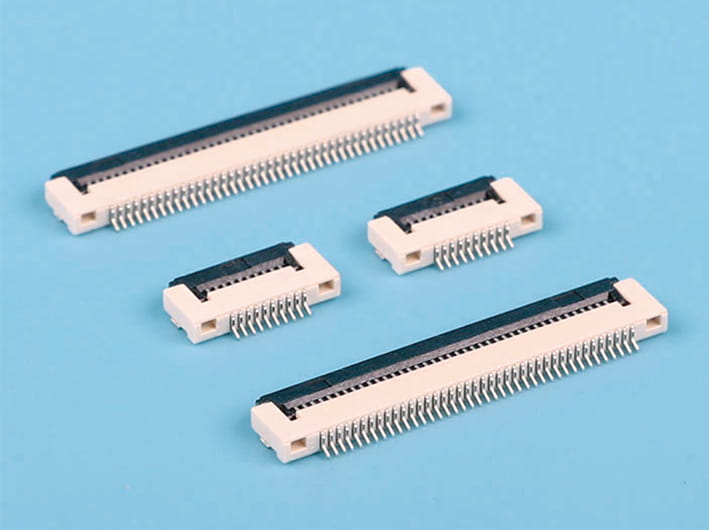

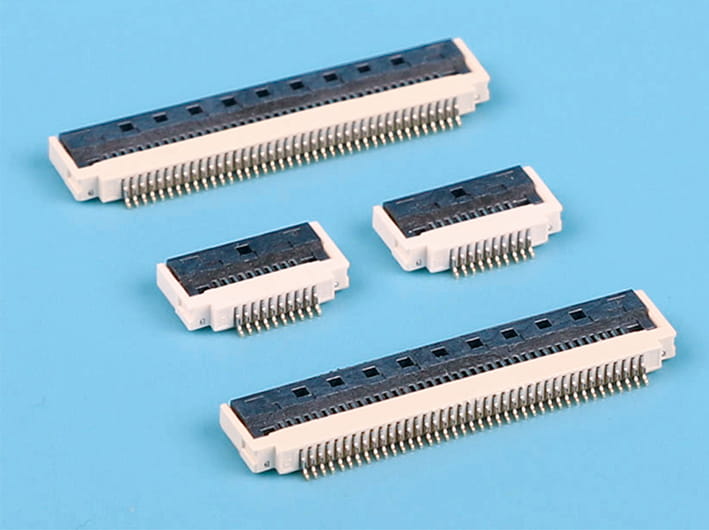

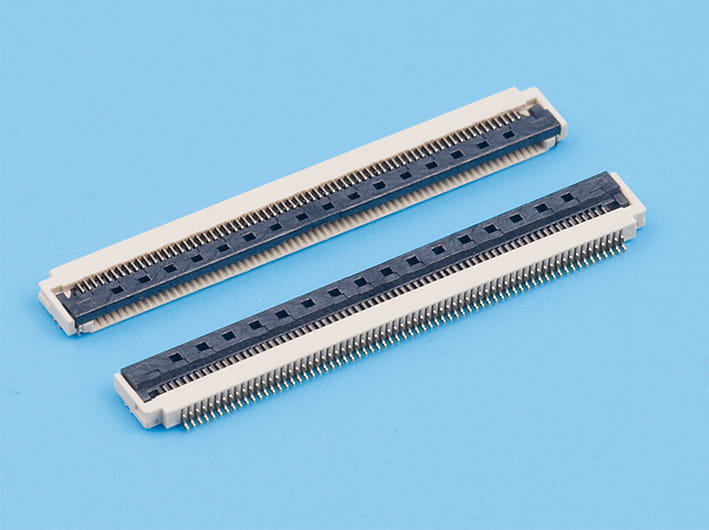

In addition to automotive board to board connectors, FPC to board connectors (Flexible Printed Circuit to board connectors) have become increasingly important in the automotive industry, particularly in the development of compact and lightweight systems for electric vehicles. FPC to board connectors are commonly used to connect flexible printed circuit boards (FPCs) to the rigid boards of various EV systems.

FPC to board connectors offer several advantages, particularly in applications where space-saving is critical. These connectors are smaller, lighter, and more flexible than traditional automotive board to board connectors, making them ideal for applications within compact, space-constrained EV systems. For example, they are widely used in sensors, infotainment systems, and powertrain control units where space is limited but performance must remain high.

Moreover, FPC to board connectors help reduce the overall weight of the vehicle, an essential factor in increasing the energy efficiency of EVs. As automotive manufacturers continue to push for lighter, more efficient designs, the use of FPC to board connectors ensures that the components are connected in a secure and efficient manner without adding excess bulk.

Key Benefits of Automotive Board to Board and FPC to Board Connectors in EV Systems

1. Enhanced Reliability

In EV systems, where electrical performance is critical, the reliability of automotive board to board connectors and FPC to board connectors is paramount. These connectors must withstand the harsh environments typical of automotive applications, including high vibrations, temperature fluctuations, and exposure to moisture and other elements. Quality automotive board to board connectors and FPC to board connectors ensure that the systems operate smoothly, avoiding downtime and costly repairs.

2. Space Efficiency

As electric vehicles increasingly incorporate more features and functions into their designs, space becomes a premium commodity. Both automotive board to board connectors and FPC to board connectors offer compact designs that allow manufacturers to optimize the use of available space. This is particularly important in areas such as the battery pack, powertrain, and sensor arrays, where real estate is limited but the need for connectivity is high.

3. Improved Data Transmission

Automotive board to board connectors and FPC to board connectors ensure reliable data transmission between components within the EV system. These connectors play a vital role in ensuring that critical systems, such as the battery management system (BMS) and power distribution units, communicate effectively. The efficiency of these connectors directly affects the overall performance of the EV, from battery life to driving performance.

4. Durability and Long-Lasting Performance

Given that electric vehicles are expected to operate in conditions, the longevity of the components is a key consideration. Automotive board to board connectors are built to last, with features such as corrosion resistance, high-temperature tolerance, and robustness against mechanical wear. Likewise, FPC to board connectors also offer durability and flexibility, ensuring that they continue to perform effectively throughout the vehicle's lifecycle.

These connectors are essential for ensuring reliable, efficient, and durable performance across a wide range of automotive systems. As EV technology continues to evolve, the need for smaller, more efficient, and more reliable connectors will only increase.

English

English 中文简体

中文简体 Español

Español عربى

عربى